Project Background:

OTML’s Processing Business Unit introduced the Structural Remediation Project Division to manage the refurbishment of the structures in the processing (mill) plant. That included the mills, conveyors, buildings, tanks and other infrastructure within the plant.

The site of the works was located within the Mill Processing Plant at Ok Tedi Mine in the North Fly District of Western Province, Papua New Guinea.

A new crushing circuit currently under construction was to be commissioned in mid year. The crusher had a design feed rate of 7,500 tph to Unit #1 Mill Feed Stockpile. Whereas the new crusher feed rate wouldl be slowed to 5,500 tph when the ore is directed to Unit #2 Mill Feed Stockpile due to the limitations of the existing CV12 conveyor.

Bechtel’s historical design documentation show CV12 had been designed mechanically for 7,000 tph, whereas the structural design was limited to 5,369 tph.

Scope of Work

The scope of work for this structure comprised structural and mechanical assessment of CV12 including findings and recommendations to strengthen, modify, improve or make safe the existing structure and equipment to support the new loads. Ideally, we were aiming to bring the design capacity of CV12 to 7,500 tph.

The scope included:

- Review original engineering designs and proposed modifications.

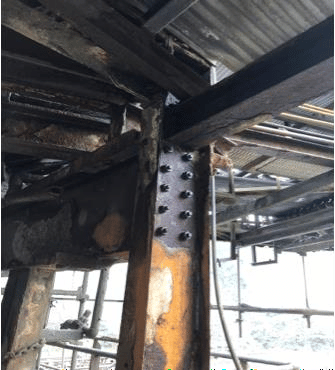

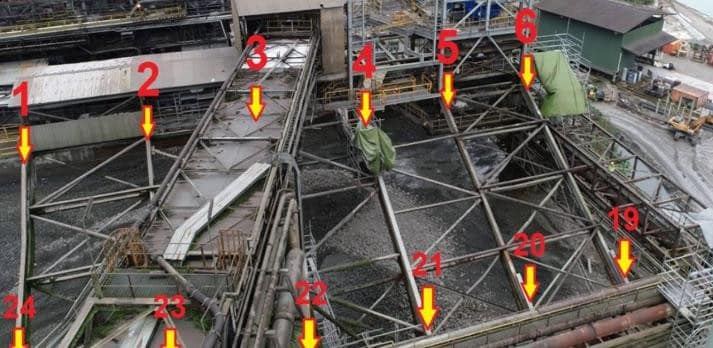

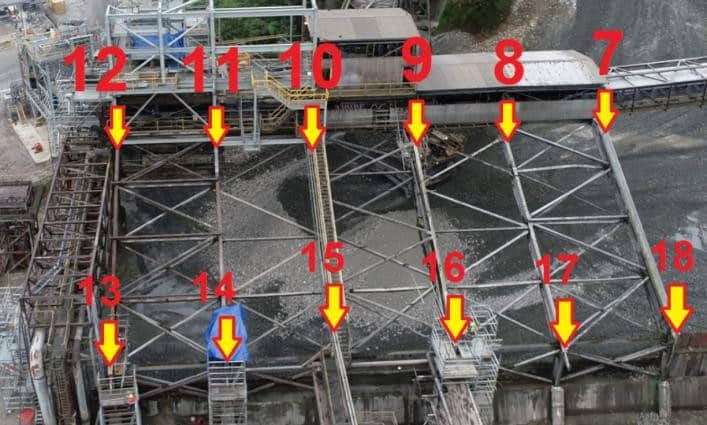

- Investigate and report the current condition of the conveyor’s steel structure and strength capacity.

- Investigate and report the current capacity of the conveyor’s mechanical equipment recommendation to improve or upgrade the existing structure and equipment to accommodate the new load capacity.

- Provide drawings detailing the upgrade works recommended for the project. The drawings will be clearly detailed and documented and completed to IFC (Issued for Construction) status.

- Provide 1 hard copy and 1 soft copy each of the documents requested above in clauses 11.1 to 11.3 to the OTML Project Team Leader.

Other key Yenem activities included:

- Review supplied data

- Initial site visit to inspect the work prior to detailed design

- Prepare calculations and models as required to ensure all structural items meet the requirements of relevant Australian Standards, Acts & Regulations

- Correspond via email, sketches, red-line mark-ups as appropriate to ensure works meet project expectations

- Submit deliverables for client approval prior to finalisation

- Review and action feedback from deliverables issued for approval

- Stamp and sign PDF copies of the final deliverables