Graduated in 1987.

Founded Yenem in 1995.

Yenem Engineering Services

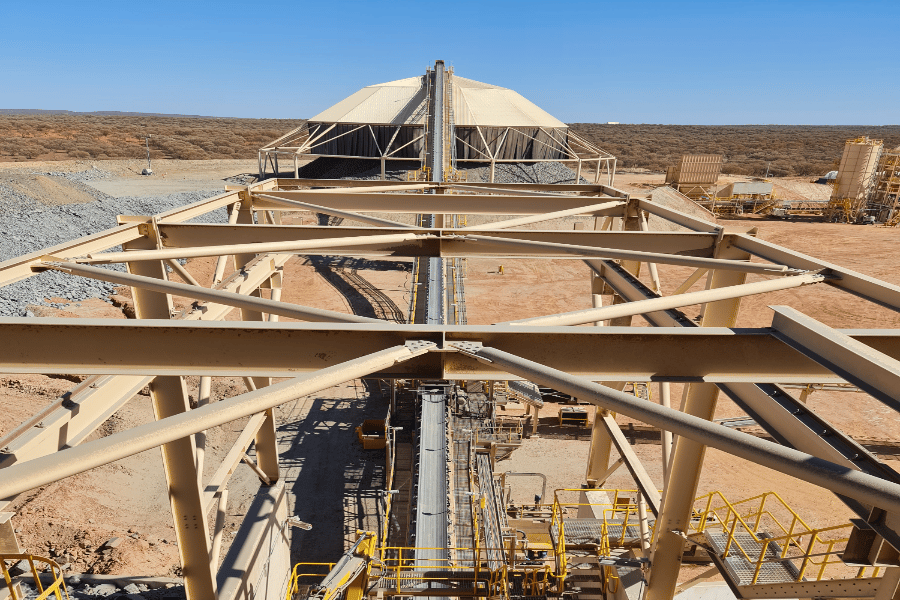

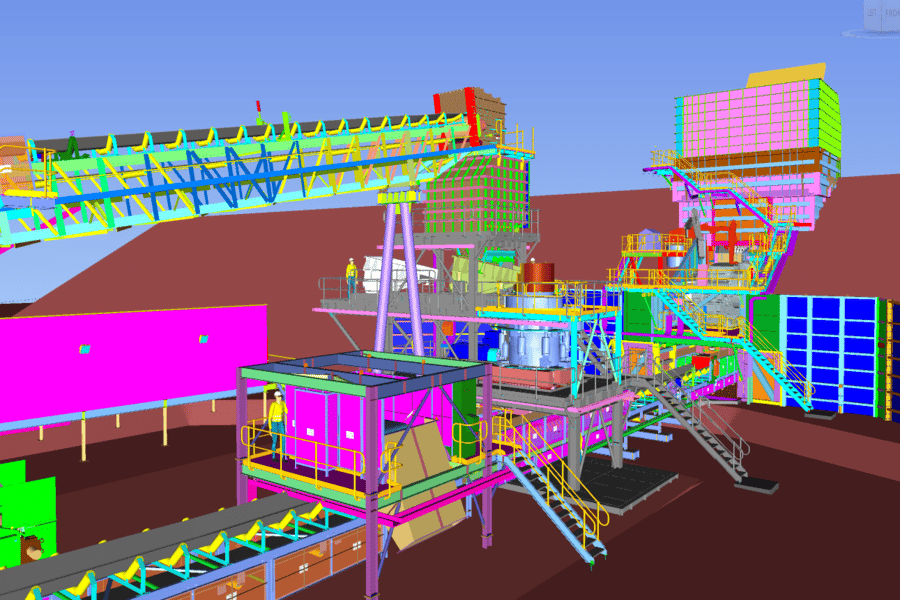

We solve complex structural problems for mining industry clients, so they have more reliable structures, increased onsite safety and fewer unplanned shutdowns.

Based in Perth, Western Australia, Yenem works with mining industry clients across Australia.

We specialise in this area, so we know we can deliver the best outcomes on structural design, inspection and remedial work for our clients.

Our expertise extends across all sizes of projects, structures and budgets. As an agile and skilled team, we are able to work closely with our clients as we rapidly create and deliver solutions that meet their needs.

As well as relying on our own research and experience, we design your structures to rules and recommendations that meet Australian Standards, the Building Code of Australia (BCA), Mining Act & Regulations, International Codes and, if you have it, your own project design criteria.

Contact us for a quote or book a free consultation today.

Structural integrity is paramount in the mining industry. Call on Yenem Engineering Services to design a reliable structure or seek our services as we review your existing assets and come up with cost-effective repair solutions, so you can avoid unplanned shutdowns or safety incidents.

Although we are one of Australia’s trusted names in structural engineering, people often pronounce it incorrectly!

No, we are not Yemen, like the country. We are YENEM, which is an anagram of our founder Dave Meney’s name.

Now you know!

Mining industry specialists

To become the most sought after engineering firm in Australia by providing the next generation of engineers experiences and opportunities to grow, innovate and serve not just our clients, but the industry as a whole.

We design practical, constructible and fit-for-purpose mining and industrial structures.

We find issues with plant structures before mines inspectors do, and propose practical recommendations to ensure ongoing safety and reliability.

We reduce our client’s stress by ensuring timely project delivery. We know what needs to be done, so you can concentrate on more important things.

BE(Civil), MIEAust CPEng RPEQ

Graduated in 1987.

Founded Yenem in 1995.