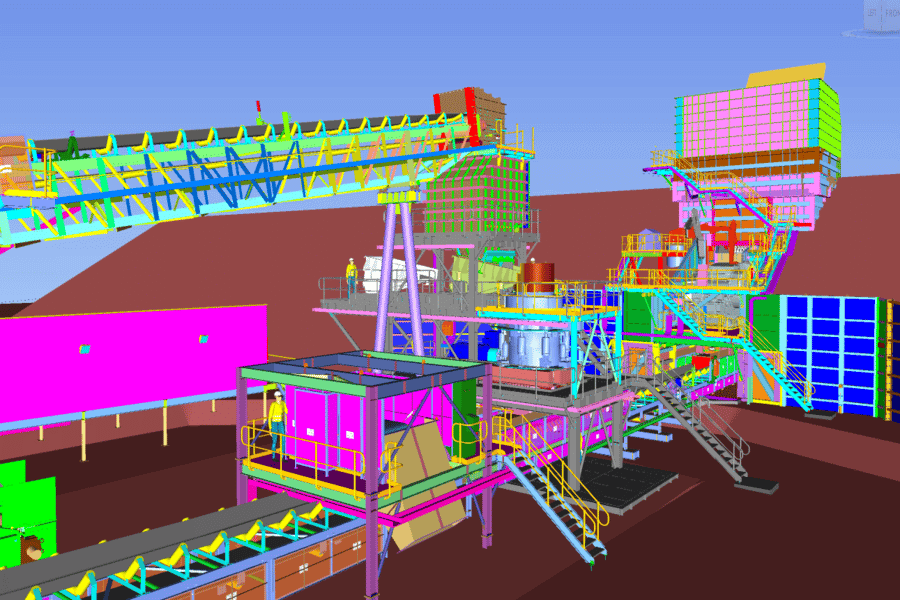

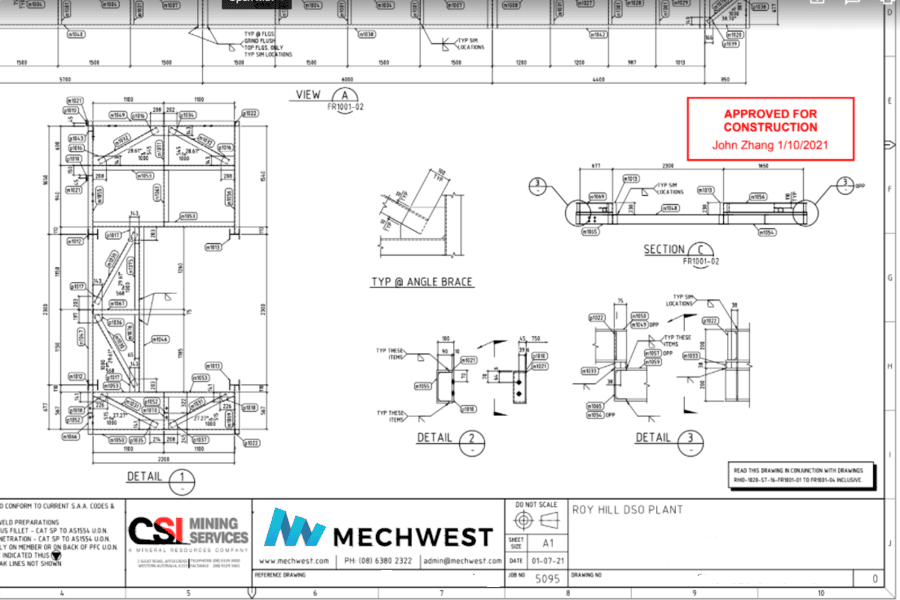

Yenem are industry experts in structural design for processing plants.

Yenem Engineering Services

The mining industry requires the support of industry-specific engineers in order to minimise shutdowns and maximise on-site safety.

Our engineering services make us the go-to providers for mining companies around Australia.

We design reliable assets that meet Australian Standards as well as client requirements.

Don’t risk the stress and expense of unplanned shutdowns. Request ongoing support from expert mining industry engineers.

Let us check the integrity and life-span of the assets on your mine site.

Regular structural inspections can identify potential issues before they become costly or dangerous.

We find the root cause of structural failures and provide an expert opinion in legal proceedings.

Yenem Engineering Services offers additional consulting and assessment capabilities.

Need an additional review? We are professional engineers registered on Engineers Australia NER and RPEQ and can provide independent review and certification of structures.

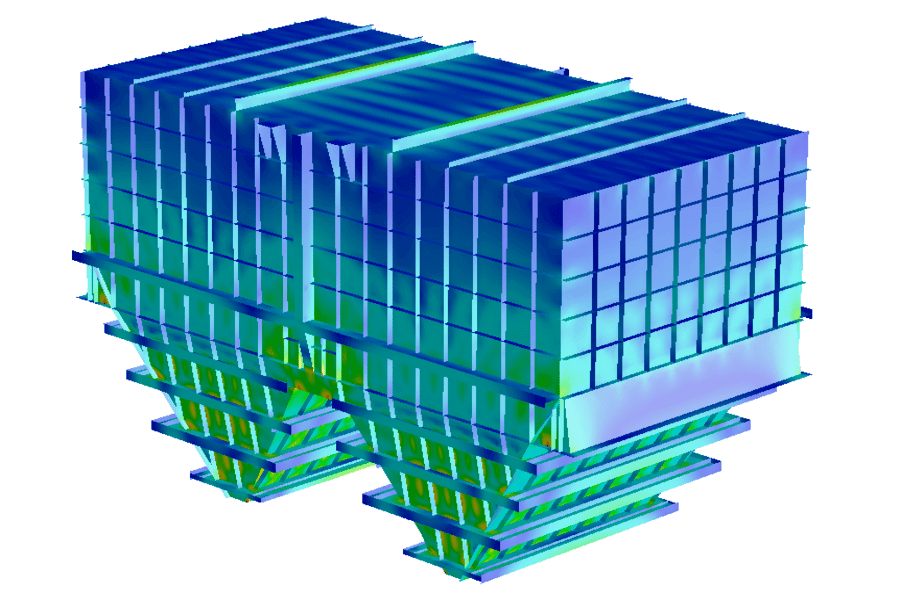

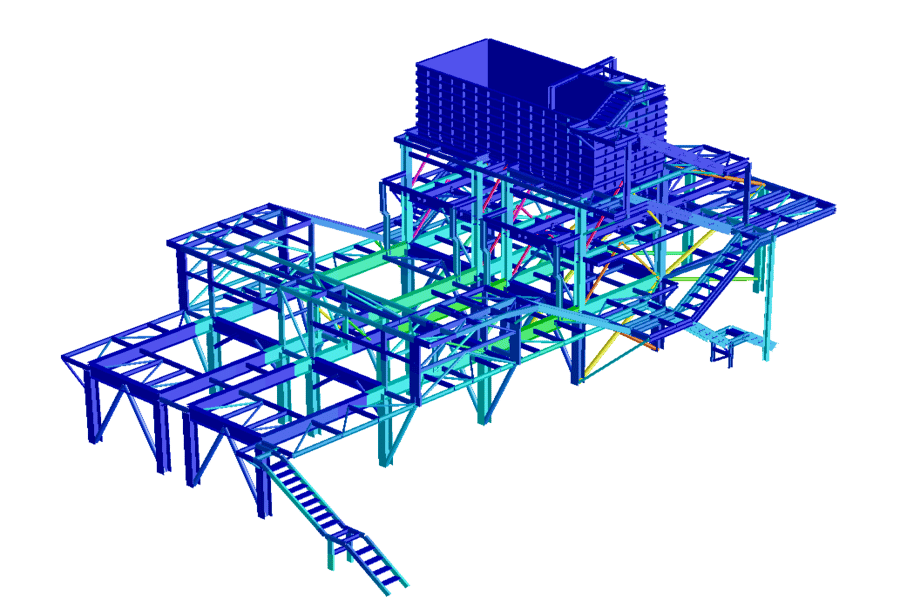

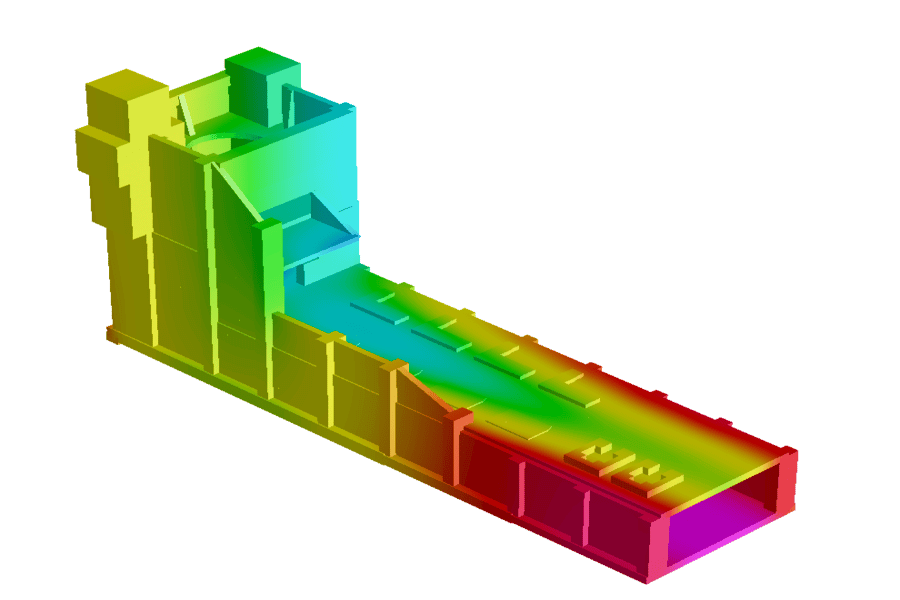

We use Strand7 and Solidworks Simulation Premium to perform complex static & dynamic Finite Element Analyses (FEA’s) on structures and equipment.

Know how much your vibrating equipment support structure will vibrate before its built, and implement design solutions to minimise the effects of vibration.

Our team utilises a scientifically driven approach to evaluate the impact of structural fatigue loading and provide an estimation of the remaining design life before potential failure.

We are not afraid to challenge the status quo and are committed to supporting you in bringing your innovative ideas to the market. Our mindset is constantly focused on exploring new and improved methods of doing things.