Finite Element Analysis Services for Mining and Industrial Applications

At Yenem Engineering Services, we deliver advanced Finite Element Analysis (FEA) solutions designed to ensure the safety, integrity, and reliability of structures in some of the world’s most demanding industries. From mining operations to heavy industry and large-scale processing plants, our FEA engineering services in Perth provide unparalleled precision in evaluating structural performance under real-world conditions.

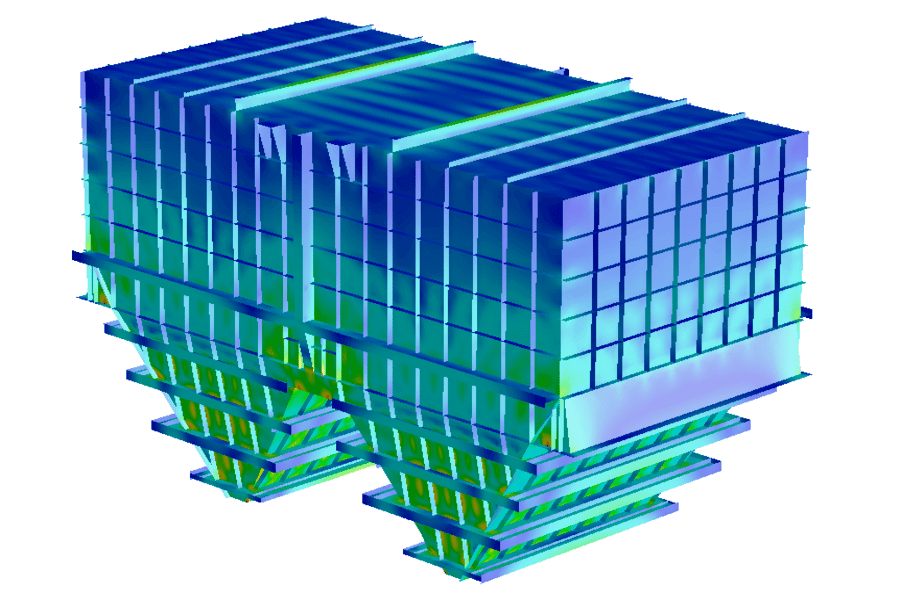

We specialise in both static and dynamic finite element analysis, offering comprehensive insights that help operators reduce risk, extend asset life, and improve overall operational safety. Using advanced tools such as Strand7 and Solidworks Simulation Premium, our engineers deliver state-of-the-art structural modelling FEA services tailored to the unique requirements of mining and industrial projects.

What is Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is a computational technique used to predict how a structure, machine, or component will behave under various physical forces. The process works by dividing a structure into small, manageable elements and simulating how these elements respond to stress, load, vibration, and environmental factors.

By running these simulations, engineers can:

- Identify potential weaknesses before they lead to failures

- Optimise designs for strength, efficiency, and longevity

- Reduce the risk of costly downtime and repairs

In industries where safety and reliability are paramount, element analysis provides the clarity needed to make confident engineering decisions before construction, installation, or commissioning.

Why is FEA Important for Mining and Industrial Structures?

Mining, heavy manufacturing, and industrial processing involve some of the harshest operating conditions imaginable. Equipment and infrastructure are exposed to extreme loads, vibration, fatigue, and environmental stressors that can compromise safety and efficiency.

Through element analysis, engineers can accurately predict how structures and machinery will perform under stress. Key applications include:

Stress analysis: Identifying areas of high stress that may cause material fatigue or equipment failure.

Structural fatigue analysis: Assessing how repeated loads impact the long-term performance of critical components.

Dynamic load simulation: Modelling real-world conditions such as vibrations, seismic activity, and fluctuating operational loads.

By integrating FEA engineering services into your project, you gain the ability to plan ahead, address vulnerabilities, and avoid unplanned shutdowns.

Our FEA Engineering Process

At Yenem Engineering Services, we follow a structured process to deliver reliable outcomes for mining and industrial clients:

- Project Review – We collaborate with your team to understand operational stresses, safety requirements, and environmental conditions.

- Finite Element Modelling – Using Strand7 and Solidworks Simulation Premium, we build detailed models of your equipment or structures.

- Simulation and Analysis – Our engineers run multiple scenarios to simulate both static and dynamic loading conditions.

- Actionable Insights – We provide clear results with practical recommendations for design optimisation, maintenance, and risk mitigation.

Advanced Structural Modelling FEA Services

Our structural modelling FEA services combine advanced software with extensive engineering expertise. We simulate how structures respond to a wide range of operational and environmental conditions, providing valuable insights that help prevent equipment failures, assess fatigue resistance, and optimise structural performance for both safety and efficiency. By delivering an accurate element analysis for plant structures, mining equipment, and industrial systems, we enable clients to extend asset life, improve reliability, and minimise costly downtime.

Beyond predicting immediate performance, our FEA services allow for long-term planning and design improvements. By understanding how structures behave under repeated loads and dynamic conditions, we can advise on material selection, reinforcement strategies, and maintenance schedules that significantly reduce the risk of unexpected failures. This proactive approach ensures that industrial and mining operations run more smoothly, safely, and cost-effectively over the entire lifecycle of their assets.

Finite Element Analysis for Equipment Failures

Equipment downtime in mining and industrial operations can lead to significant losses. Our engineers use FEA’s to simulate potential failure scenarios and predict how equipment will respond to extreme loads, wear, and fatigue.

This proactive approach allows operators to:

- Prevent unexpected failures

- Improve maintenance schedules

- Implement design improvements before issues arise

By applying FEA engineering services early, you safeguard both operational efficiency and worker safety.

Dynamic Load Simulation

Dynamic loads are among the most challenging factors for mining and industrial infrastructure. Using finite element analysis, our engineers simulate the effects of vibrations, seismic activity, and fluctuating operational forces on plant structures. By modelling these complex interactions, we can predict how equipment and structures will respond under varying conditions, ensuring that critical systems remain safe and functional.

In addition to assessing immediate structural responses, our dynamic load simulations provide insights into long-term performance and resilience. By understanding how repeated or variable forces affect fatigue and stress distribution, we can recommend design optimisations, reinforcement strategies, and maintenance schedules that minimise the risk of failure. This proactive approach allows industrial operators to maintain high levels of safety and operational efficiency, even in environments subject to constant or unpredictable dynamic forces.

Stress Analysis and Structural Health Monitoring for Plants

Effective stress analysis is fundamental to understanding how structures respond to operational demands such as heavy machinery, heat, or vibration. In addition, our structural health monitoring solutions provide ongoing insights into infrastructure performance, helping operators take corrective action before problems escalate.

Get Started with Yenem Engineering Services

If you need expert FEA engineers in Perth who understand the complexities of mining and industrial operations, Yenem Engineering Services is ready to help. Our advanced element analysis services provide the insights you need to improve safety, reliability, and efficiency.

We offer:

- Stress and fatigue analysis for mining equipment

- Dynamic load simulation for industrial facilities

- Finite element analysis for plant structures and machinery

- Ongoing structural assessments and inspections

Book a free consultation or request a quote today and discover how our FEA services can strengthen your next project.