Top Structural Risks to Address Before Cyclone Season

When it comes to mine site safety, the most dangerous hazards are often the ones you don’t see. Not every threat comes with flashing lights or warning signs. Some of the most serious dangers are hidden in plain sight, quiet, forgotten, and slowly undermining the very assets meant to keep your operations running.

At Yenem Engineering Services, we’re increasingly seeing these hidden structural risks across mining operations. Many arise from temporary fixes that became permanent, overlooked maintenance, or small modifications that compound over time. Ignoring them isn’t just risky, it can be catastrophic during a cyclone or extreme weather event.

Here’s a closer look at eight common risk zones we find on mine sites, and why addressing them now is critical to preventing future incidents.

1. Temporary Structures That Refuse to Leave

Scaffolds, props, and temporary platforms are built for short-term use, but often remain long after shutdowns. These “temporary” structures were never engineered for long-term loads, vibration, or exposure to harsh weather.

When left unattended, these structures create hidden structural risks that may go unnoticed until they fail. What started as “we’ll remove it next week” can linger for months or years, quietly increasing liability and safety concerns.

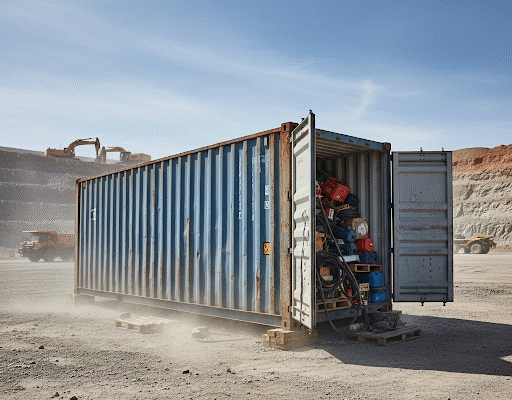

2. Freight Containers Used as Permanent Structures

Shipping containers are convenient, durable, and cheap, but using them as long-term storage or office space introduces significant structural risks. Overloaded containers, stacked without engineering checks, or left unsecured on uneven ground can fail under wind, rain, or cyclones.

Originally designed for transport, not as permanent buildings, containers are vulnerable to uplift forces, lateral loads, and modifications that compromise their integrity unless they’ve been engineered. Yet they’re often used as workshops, chemical stores, and offices, places where failure is not an option.

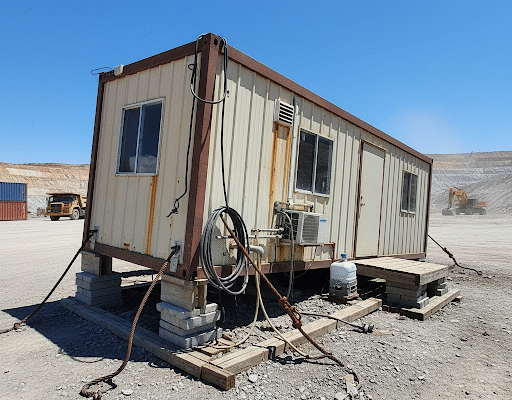

3. “Temporary” Demountables That Become Permanent

Demountables and site offices are intended for temporary use, but many remain in place for years. Foundations shift, tie-downs rust, and small additions accumulate over time.

These long-standing demountables introduce ongoing structural risks because their original design compliance and load capacity can no longer be guaranteed. The structure may still look fine, but under extreme conditions it could fail, putting personnel and assets at risk.

4. Buried or Corroding Column Bases

Steel supports often become partially buried under spillage, backfill, or vegetation. Once hidden, these critical bases are out of sight, and out of mind until the unthinkable happens.

Unknown corrosion or foundation damage is one of the most insidious structural risks on a mine site. A column failure could cascade into widespread structural issues, especially during high wind events.

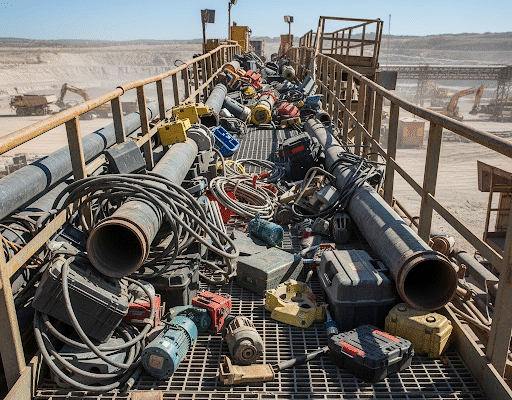

5. Walkways and Platforms Taking More Load Than They Should

Platforms designed for foot traffic are often repurposed for storage. Slowly, tools, spare parts, piping, and spillage increase the load beyond the original design.

These hidden structural risks accumulate quietly. Without reassessment, what seems minor today could be a significant safety hazard tomorrow.

6. Retaining Walls and Earth Structures Showing Early Warning Signs

Hairline cracks, slight leaning, and minor water buildup often appear harmless, but these are early indicators of potential collapse. Proactive inspections and maintenance are key to mitigating these structural risks before they escalate into costly and disruptive remediation projects.

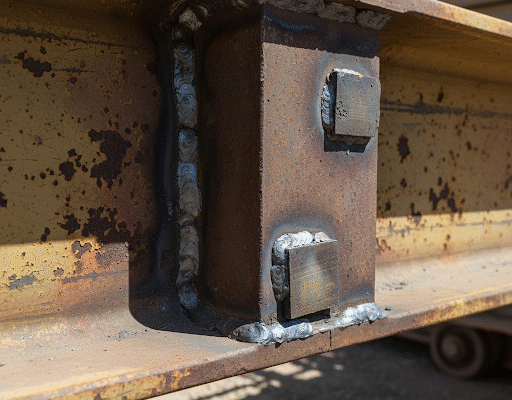

7. Weld Repairs and Structural Modifications Done on the Fly

Quick fixes like onsite welds, stiffeners, or modifications can get a plant operational again, but undocumented and unverified repairs introduce significant structural risks. Over time, patchwork solutions undermine structural integrity, reliability, and long-term safety.

8. Missing or Blocked Stormwater and Wind Bracing

Cyclone season leaves no room for oversight. Blocked drains, removed cross-bracing, and missing ties may seem minor, but they can compromise entire systems. These small components play a major role in preventing structural risks from turning into real disasters.

Deal With Hidden Structural Risks Before They Deal With You

Now is the time to act. Reviewing, assessing, and remediating these hidden structural risks before the next cyclone season can save money, prevent downtime, and most importantly, protect your team.

At Yenem, we specialise in identifying these blind spots and providing practical, compliant, and reliable structural engineering solutions tailored to your mine site. Don’t wait for an incident to highlight the problems, address them now.

Book a free call today and make sure your mine site is cyclone-ready and structurally secure.