Advancing Engineering Solutions for Today’s Extreme Mining Environment

Mining operations can often take place in the harshest mining environment on Earth. From scorching deserts to sub-zero tundras, these extreme conditions pose unique challenges for the structures and equipment that keep mines running. As engineers, it’s our job to design and build mining infrastructure that can withstand the toughest conditions while optimising performance and cost-efficiency.

Selecting the Right Materials

Material selection plays a critical role in ensuring the longevity and performance of mining structures in an extreme mining environment. In a recent project for Rio Tinto, we re-designed a corroded conveyor system, strategically using stainless steel sections below the belt and mild steel above. This material choice saved costs by minimising the use of expensive stainless steel, while providing the necessary corrosion resistance where it mattered most.

When it comes to structural steel, it’s essential to consider the impact of extreme temperatures in the mining environment. Steel expands and contracts significantly under temperature fluctuations, which can lead to damage if not accounted for in the design. By using clever design tricks, such as allowing for controlled movement and using expansion joints, we can minimise the detrimental effects of thermal expansion and ensure the structure’s integrity.

Designing for Extreme Winds

In regions prone to cyclones and high winds, engineering structures must be designed to withstand these powerful forces especially in the mining environment. Traditional design approaches often result in overbuilt, uneconomical structures. However, by thinking outside the box, we can create designs that are both resilient and cost-effective.

One strategy is the strategic placement of openings in buildings, allowing wind to pass through and reducing the structure’s overall wind load. Another approach is using aerodynamic sections, which can help to minimise wind drag and improve the structure’s stability. By carefully considering wind forces in our designs, we can create mining structures that stand strong even in the face of an extreme mining environment.

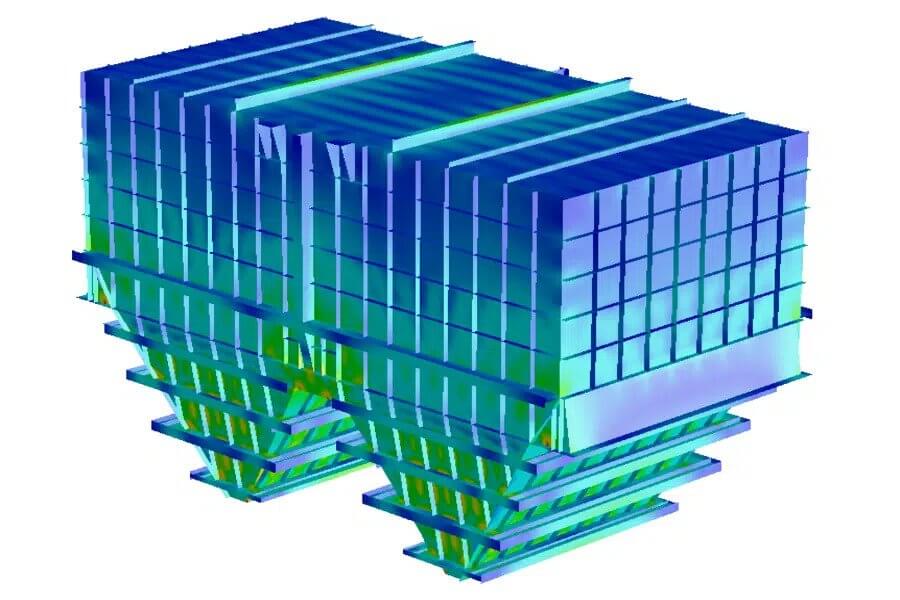

Modular Construction for Remote Locations

Mining operations are frequently established in remote, hard-to-reach regions and in a far flung mining environment where access to traditional construction resources is limited and expensive. In such environments, the logistical challenges of transporting materials, sourcing skilled labour, and maintaining construction timelines can significantly drive up costs and delay project completion.

One of the key advantages of modular construction is its adaptability to challenging terrains, climates, and the unique demands of the mining environment. Since much of the fabrication is done off-site, the risks associated with weather delays, limited infrastructure, and workforce shortages are greatly reduced. Additionally, the modular components are designed for ease of transport, allowing for efficient delivery via truck, barge, or even helicopter when necessary.

Furthermore, modular construction ensures consistent quality and safety standards, as units are built under controlled conditions with regular inspections. This leads to more durable, reliable structures that can withstand the demanding conditions of a remote mining environment.

By embracing modular construction techniques, mining companies can achieve faster project delivery, improved cost control, and enhanced sustainability. This makes it possible to build high-performance, long-lasting facilities even in the most inaccessible regions.

The Importance of Regular Inspections and Maintenance

Even the most well-designed and constructed mining structures require regular inspections and maintenance to ensure their ongoing performance and safety. Harsh mining environments can take a toll on even the toughest materials, leading to corrosion, fatigue, and other forms of deterioration.

By implementing robust inspections and a maintenance program, mining companies can identify and address potential issues before they escalate into major problems. Regular structural assessments, using advanced techniques such as drone surveys and 3D walkthroughs, can provide information into the condition of mining infrastructure, allowing for proactive maintenance and repairs.

Engineered for Extremes. Designed by Experts.

In mining, the environment is the test. From desert heat to arctic cold, we design structures that are smart, efficient, and built to last.

At Yenem Engineering, we deliver resilient infrastructure for the harshest conditions; with modular solutions that simplify logistics and cut downtime. And because prevention is key, our advanced inspections keep your assets strong, year after year.

Is your infrastructure ready for the extremes? Book a consult today for an engineering solution to help fill your needs.

Conclusion

Engineering in the most extreme mining condition requires a multifaceted approach, combining clever material selection, innovative design strategies, and efficient construction techniques. By carefully considering the unique challenges posed by harsh environments, we can create mining structures that are built to endure, ensuring the safety, productivity, and profitability of mining operations for years to come.