As a young engineer, that’s what they called me. The lean, keen, structural machine!

A skinny, nerdy young bloke, still wet behind the ears, that never understood the need for excessive design, or over-design, and saw it as incompetence.

My designs attracted many questions from the drawing office and feelings of nervousness from my bosses. And sure, I learned that sometimes bigger was better, especially when I tried to replace walkway beams with angle iron that couldn’t be bolted!

I learned from arguably the best two structural engineers Perth had, and I stood by my designs. In fact, my first boss (a mechanical engineer) made me stand under one of them – a cyclone support structure that he reckoned would collapse it was that lightly designed (it was fine, didn’t flinch an inch!).

A cyclone cluster, used in mineral separation

Over time, I gained the respect of the structural drafters that have also taught me useful concepts such as constructibility.

My reputation, and that of Yenem generally, is we’re lean. We don’t waste materials. We understand materials and their behaviour, and we provide constructible, economical, efficient designs. Why wouldn’t we? Is that not our charter as engineers?

I’ve checked some structures that were that far over-designed I wondered why calcs and models were done in the first place! Respectable company names in drawing title blocks quickly became unrespectable to me.

I wondered if over-design was a front for incompetence. Perhaps if a design is much larger than it need be, it will still be okay if it was designed wrong. I did find that in some cases. Gross errors in loading calcs that, thanks to over-design, meant the structure as drawn was still okay once it was designed properly. But that’s not a justification for over-design, is it?

I noticed that some engineers became more conservative as they got older. What’s with that?

I noticed that many conservative engineers came from large EPCM companies. What a shame that the companies that seek out accolades by winning design awards have a seemingly limited talent pool. Perhaps it’s a structure’s uniqueness and aesthetic appeal that wins the awards, rather than the prowess of the engineering team?

I wonder how much extra steel and concrete has been used in the country and indeed the world due to conservative design. A world that is fast becoming extinct in raw materials and heating up as we extract and process them.

An ironic thought – our industry over-designs steel structures in an iron-ore processing plant, built to mine ore, in order to manufacture steel to make structures! Lol!

Ore Mining

I don’t think climate change was on my mind back in that smokey office in 1993 as I gained my reputation for being lean. But it’s certainly something to think about these days.

Material strengths are generally well understood and well-defined, and codes deal with the remaining uncertainty through partial safety factors on materials and loading. There should, therefore, be no need to add a further ‘factor of safety’ by increasing member capacity.

Similarly, the thoughtless application of design codes results in either overdesign (which is wasteful) or under-design (which is dangerous). The importance of understanding each code clause and where it needs to be applied must not be underestimated.

To say it takes too long to “do it properly” using higher-tier code methods is not being true to our charter nor our climate. And yet here we are, trying to compete in an industry that measures us by the hours we take. An hour costs a couple of hundred bucks. The steel saved would have cost thousands of dollars per tonne.

Structural failures, and there are plenty of these, aren’t usually due to ‘lean’ design. Understanding of a structure’s purpose and function combined with sound and appropriate use of codes is unlikely to ever be the cause of a structural failure.

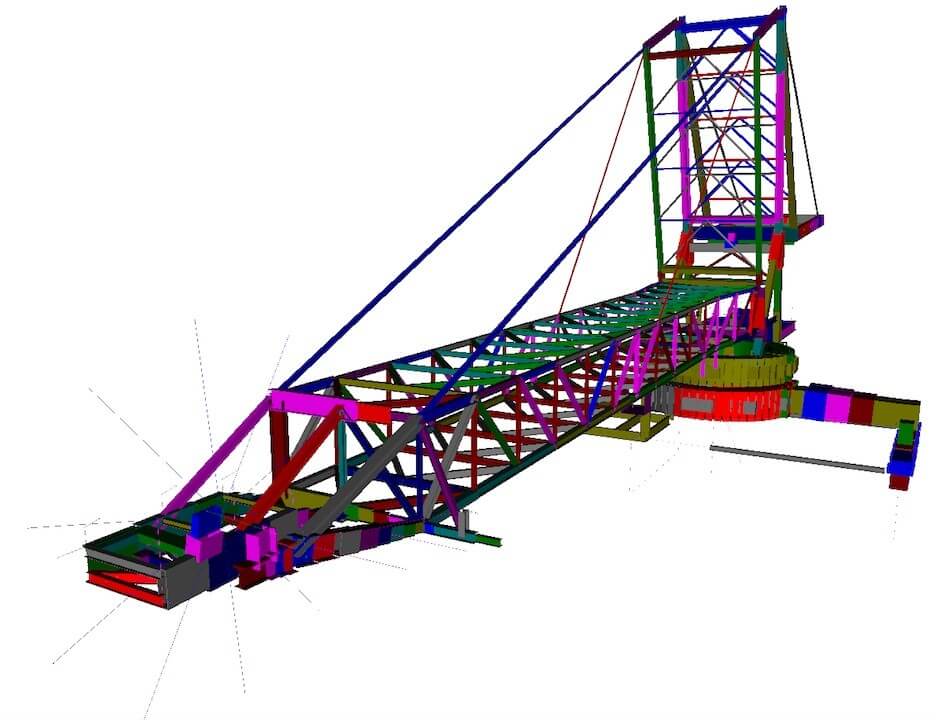

Reclaimer-Failure (Image courtesy of Mining Mayhem)

On the other hand, creating a culture of overdesign that leads to overloading by clients beyond design limits, could.

The best we can do is an appropriate design, with a mindset of saving materials and construction labour to create economical and constructible structures.

The worst we can do is bump up the size of some members to “make them look good” without realising an overload situation could then result in a brittle or catastrophic failure of a member or connection.

For example:

1. We’d prefer a member fails in bending before shear if overloaded.

2. We’d prefer a connection was stronger than the members connected to it.

3. We’d prefer a column is stronger than a beam in a portal frame to prevent sudden and catastrophic failure of a column in the event of a seismic or wind overload.