Should you be concerned when you see a crack in a concrete wall or slab?

Well, that depends. There are two classifications of cracks in concrete – structural, and non-structural. You should be immediately concerned about a structural crack. And you should be concerned about durability with a non-structural crack.

In the residential arena, you’d be told it’s not structural unless you can stick your finger in it.

But in my cynical opinion, the code that assesses those residential cracks was written by builders for builders!

Structural cracks may endanger the safety and durability of a structure. They can form due to incorrect design, faulty construction and/or overloading.

The cracks in the Opal Tower in Sydney were structural cracks, for example. The finding, in that case, was under-design of a precast concrete element. And yep, people had a right to be concerned!

Non-structural cracks are mostly formed due to internally induced stresses in building materials and do not result in weakening of the structure. However, if left untreated, a non-structural crack may facilitate ingress of moisture and other destructive environmental substances, which may lead to corrosion of reinforcement, potentially making the concrete structure unsafe.

Cracks that are identified as small and fine (less than 0.3 mm in width), are generally deemed acceptable as part of minor settlement depending on the purpose and intent of the concrete structure, the environment it is placed in, the design life and the durability requirement.

Nevertheless, an experienced and competent structural engineer should be consulted to classify the severity of cracks in concrete and appropriately investigate the cause of the cracks and determine the most effective repair method if required.

6 Main Causes of Cracks

Cracks are mainly caused by:

-

- Plastic Settlement

- Plastic Shrinkage

- Thermal Contraction

- Drying Shrinkage

- Crazing

- Corrosion of Reinforcement

1. Plastic Settlement

These cracks form while the concrete is still plastic, during the initial setting of concrete. At this time, bleed water is still rising and it covers the surface while the aggregate and cement settle under the force of gravity. This separation forms a weaker layer of concrete near the surface. These types of cracks occur on the surface before the concrete has set. Plastic settlement cracks are typically mirroring the pattern of the restraining elements such as reinforcement. Plastic settlement cracks are often identified in deep section pours, such as on top of beams and columns.

2. Plastic Shrinkage

These cracks form due to rapid early drying and a low rate of bleeding while the concrete is still plastic (not set). Plastic shrinkage occurs mainly in concrete elements with a high rate of surface to volume such as slabs and pavements. Air and concrete temperature, wind speed, the warming and drying action and relative humidity all play an important role in the rate of moisture evaporation from setting concrete. Plastic shrinkage cracking occurs when the rate of evaporation from the surface exceeds the rate at which moisture is being supplied to it (via bleeding from the concrete).

Rapid drying of the surface of the concrete causes it to shrink and crack (similar to the cracking that occurs in clay soil as it dries). The cracks are not always evident and may not be discovered until the next day.

Plastic shrinkage cracks may form in a random pattern or they can appear in an almost parallel pattern. The cracks are often almost straight, ranging in length from 25 mm to 2 m but are usually 300 to 600 mm long. They can range from 1 to 3 mm wide at the surface and are superficial.

3. Thermal Contraction

These cracks occur in large concrete pours because the internal temperature of the concrete slab rises and drops slowly – due to concrete’s exothermic reaction – while the external temperature of the slab cools rapidly due to the ambient temperature.

The cooler portion of the concrete contracts more than the warmer portion. This leads to stresses greater than the tensile strength of the concrete and early thermal cracks appear.

Changes in ambient temperature conditions from moderate day-time temperature to low night-time temperature may cause rapid cooling of the exposed surface of the concrete and the contraction is likely to cause thermal cracking.

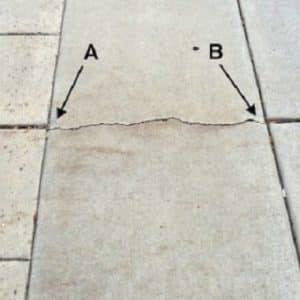

4. Drying Shrinkage

Concrete shrinks as it cures due to the loss of moisture in the concrete. If the concrete was free to shrink it would not crack, but all concrete structures are somewhat restrained from shrinking and so reinforcement and crack control joints are provided to minimise the cracking.

The most common locations where long-term drying shrinkages occur are in thin floor slabs and walls, typically along an ineffective joint.

Long-term shrinkage in concrete depends on a number of factors, e.g. cement and water content, size of aggregates and aggregate-cement ratio, the spacing of reinforcement steel, excessive fines, use of admixtures, the composition of cement, temperature, humidity and inefficient curing.

5. Crazing

Crazing is the development of fine random cracks on the surface of the concrete caused by shrinkage of the surface layer. It is caused by drying out of the concrete surface, particularly when the surface has been exposed to low humidity, high air or concrete temperature or hot sun and wind during placement of the concrete mix.

Apart from appearance, crazing cracks do not usually affect the structural integrity of the concrete but may lead to subsequent deterioration.

6. Corrosion of Reinforcement

The high pH (alkalinity) of concrete forms a passive film on the surface of the embedded reinforcing steel bars and acts as a protective shield that prevents or minimises corrosion. Reduction of the concrete’s pH by carbonation or the ingress of chlorides (salt), which are the most common causes of concrete corrosion, causes the steel’s passive film to degrade. Rust begins to form on the unprotected reinforcing steel.

The build-up of corrosion causes tensile stresses in the concrete as the bar grows in thickness. The pressure causes the concrete to form cracks near the steel that will with time lead to more extensive cracking as the rust builds up until the concrete starts to break away from the reinforcing steel bars (spalling of concrete) and expose the corroded reinforcing steel bars.

What cracks do you have?

If you have concrete structures that are cracked, it’s important to understand if they are structural or non-structural, and dormant or non-dormant. That’s where we can help, and we don’t always have to visit your site. Often, a photo and a design drawing is all we need to determine the type of crack and whether or not you may have a problem.

Non-structural cracks can be repaired if necessary for aesthetics or durability. But identifying the likely cause of the cracks and whether they are dormant or not is important before any repairs are carried out.

Minimising Cracks in Concrete

Whilst many cracks in concrete can be repaired, you’re better to prevent or at least minimise them through good design (appropriate reinforcement and joint locations) and proper construction.

Attention to detail, a project-specific concrete specification, and good quality control and supervision during construction will all contribute to a concrete structure that lasts the duration of its design life and look good too.