Applying the Swiss Cheese Model to Mining Structures and Why It Minimises Shutdowns

Anyone who has worked around processing plants, quarries, or mine-site infrastructure knows this: behind every conveyor, crusher building, or platform is a chain of decisions, assumptions, and on-site realities. When something fails, it is rarely a single mistake that is to blame. More often, failure emerges from the quiet stacking of small gaps across design, construction, and operation.

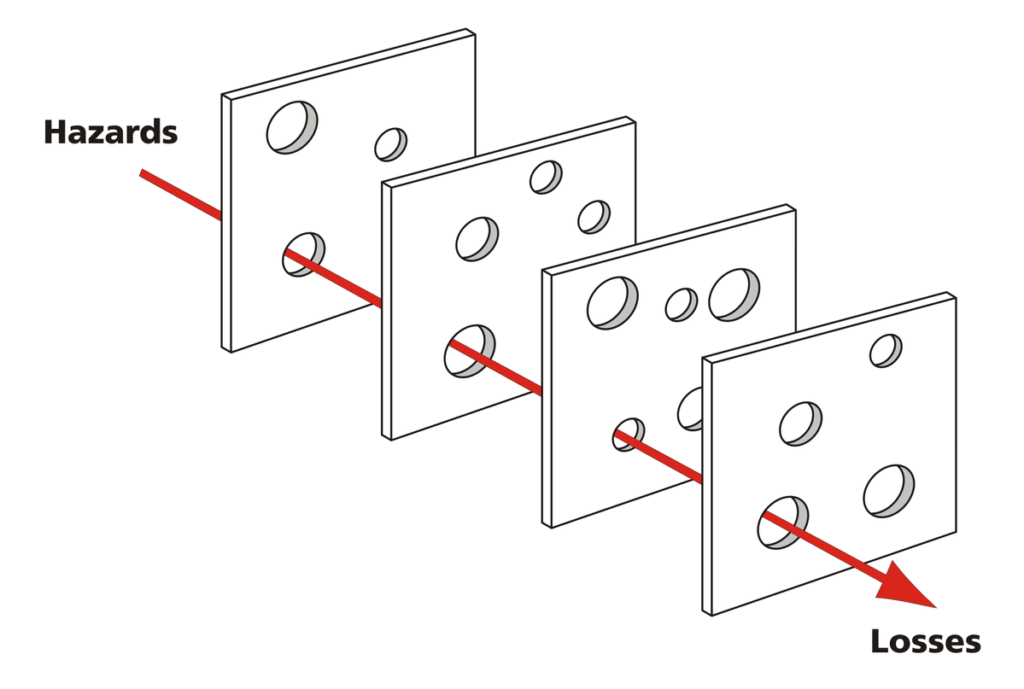

That is why the Swiss Cheese Model is such a powerful lens for structural engineering. It helps us see how small imperfections such as missed details, unrecorded modifications, and unnoticed wear can align over time and eventually result in cracking, deflection, corrosion, or catastrophic failure.

Understanding the Swiss Cheese Model in Mining Structures

Originally developed by psychologist James Reason, the Swiss Cheese Model frames failures as the consequence of multiple small weaknesses lining up across different layers of defence. For mining structures, each “slice” of cheese represents a critical stage where errors or omissions can occur, from the original design assumptions and fabrication quality to installation, operational use, and ongoing maintenance.

No single gap will usually cause failure on its own. One small miscalculation in equipment loads, one unnoticed corrosion spot, or a minor undocumented modification may seem trivial. But when several of these holes align, the consequences can be severe, including equipment damage or even plant shutdowns.

Why This Matters for Structural Inspections of Degrading Assets

Mining structures do not fail overnight. They degrade gradually because loads increase as production grows, modifications go undocumented, fatigue accumulates around vibrating machinery, and corrosion and wear progress silently. Quick repairs during shutdowns, often completed without full design oversight, create further holes in the system.

At Yenem, inspections are approached through this Swiss Cheese lens. A structure is not seen as a collection of disconnected elements but as an interconnected system. By reviewing design intent, assessing current conditions, validating load paths, identifying potential risks, and providing practical, actionable recommendations, inspections go beyond mere defect reporting. They actively manage structural risk.

Our inspection approach treats every structure as a complete system rather than a collection of isolated parts. We review the original design intent to understand what loads it was built to handle, assess current conditions to identify what is deteriorating and why, and validate load paths to ensure forces are travelling as intended. We pinpoint potential risks that could lead to future failures and provide practical, on-the-ground recommendations that go beyond simply listing defects. This is not a “tick-and-flick” assessment. It is proactive structural risk management that protects assets and minimises unexpected shutdowns.

Design Work: The Front-End Slice of Swiss Cheese

Effective design provides the first line of defence. By developing accurate loads, clarifying detailing, providing constructible solutions, and maintaining audit-ready documentation, engineers minimise the early holes that could align later during operations. Robust design anticipates future modifications, operational demands, and shutdown works, creating a resilient structure from day one.

Inspections are the later slices, catching gaps that appear during construction, operation, and ageing. The real value lies in understanding the entire block, not just individual slices.

Minimising Shutdowns: The Real Benefit

Mining production depends on uptime. Even a single misalignment, crack, or unverified modification can halt a conveyor, stop a screen house, immobilise a stacker, or shut down an entire plant. The Swiss Cheese Model reminds us that these shutdowns are not bad luck. They result from small issues lining up across multiple stages.

By addressing each layer including design, fabrication, construction, operation, and inspection, engineers can break this alignment and prevent failures before they occur.

A Practical Approach for Engineers and Inspectors

Every stage of a structure’s lifecycle needs attention. Confirming actual equipment loads, documenting assumptions, checking for undocumented modifications, accounting for vibration and fatigue, monitoring corrosion, and understanding changes in operational use are all critical. Each slice addressed reduces the likelihood of failure and protects production uptime.

Conclusion: The Swiss Cheese Model as a Reality Check

In mining and industrial environments, risk is not static. It grows, shifts, and accumulates, often invisibly. The Swiss Cheese Model is a constant reminder that design protects the asset at the beginning, inspections protect it later, and the most serious failures occur when weaknesses across all layers align.

At Yenem Engineering Services, the goal is to find these holes early in design, operation, or ageing infrastructure and close them long before they cause shutdowns. This approach is not theoretical. It is practical, defensible engineering that keeps Australia’s toughest projects running safely and efficiently. Book your consultation today and let us show you how proactive, model-driven inspections can save time, reduce costs, and protect the safety and integrity of your structures for years to come.