We have some of the largest temperature gradients in Australia, and this simply means a huge difference between the coldest and hottest temperature.

What’s this got to do with structures? Well quite a lot, actually. All materials expand and contract with changes in temperature. In the cold, things shrink!

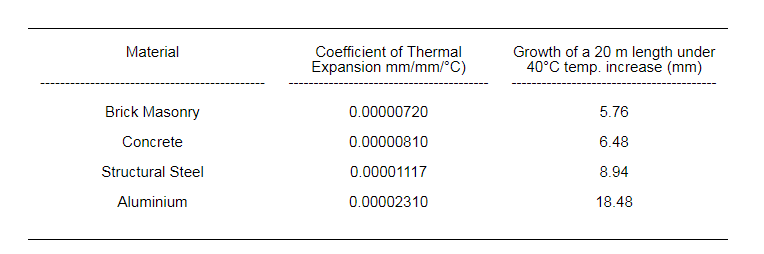

Some materials are more susceptible to thermal expansion than others. Brick masonry, for example, has a very low coefficient of expansion whilst aluminium has the highest coefficient amongst the common construction metals.

This is interesting since aluminium window frames sit inside brick openings on pretty much every house in Australia. This is not a problem, so long as it is known and detailed accordingly.

Time and again, it’s the detail that requires careful consideration to ensure a project’s success.

Being aware of thermal expansion is just one aspect of a good structural engineer’s knowledge.

Good design incorporates so many things that go unnoticed on drawings but stand out during or after construction if not done well.

For example, long structures are susceptible to building growth. Typical examples are conveyors and large warehouses.

Thermally Susceptible Structures

The change in temperature is based on the installed temperature. For example, a structure erected early on a winter morning with a surface temperature of 5 degrees will experience a gradient of 40 degrees if exposed to a surface temperature of 45 degrees in the summer heat.

Thermally susceptible structures should not be erected at extreme ends of the temperature range.

AS/NZS 1170.1 provides guidance on temperature gradients for various regions in Australia. In our interior northwest, where the majority of our mining structures are built, the design temperature gradient is over 50 degrees celsius.

For a gradient of 50 degrees, a 100 m long building or conveyor will grow 56 mm in length. That’s likely more than the tolerance allowed, and careful attention to detail is required.

When surveying thermally susceptible structures, consideration must be given to the installed temperature and the current temperature. Monitoring buildings and structures over time should take into account the change in temperature between readings.

The growth of steel structures can’t be stopped, but the direction it grows in most definitely can.

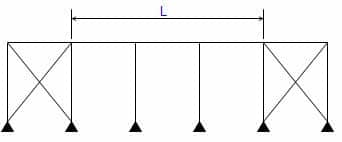

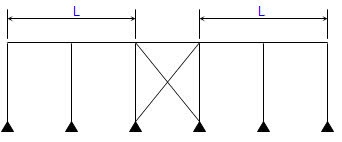

In the sketches illustrated below, the option 3 bracing system results in a building that minimises thermal expansion. It also contains less steel and connections!

- Option 1

- Option 2

- Option 3

Despite this, I see a lot of Option 1 in large workshop and shed structures.

Thermal Expansion in Conveyor Structures

Conveyors are generally made up of several steel trusses supporting the belt, spanning between support trestles, buildings, take-up frames and drive towers.

Careful consideration should be given to the locations of fixed and sliding joints. A lack of detail here means a conveyor with poor tracking and endless maintenance issues.

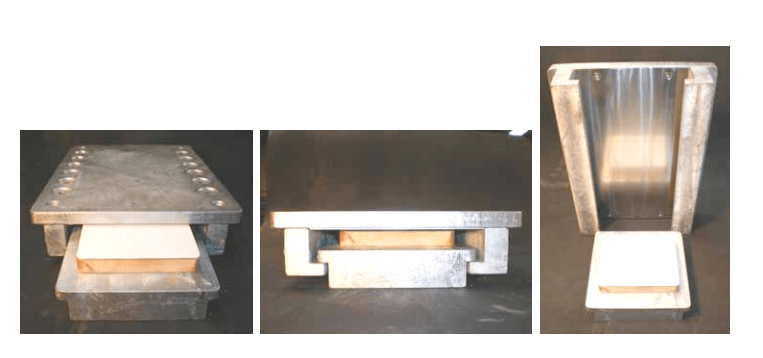

We use a combination of sliding joints and fixed joints to minimise thermal growth in long conveyor structures and locate them to balance the growth of the trusses in both directions. Typically we’ll use “Series BGSU” bearings by Granor (or equivalent!). These have uplift restraint whilst permitting longitudinal movement u to 40 mm.

Conclusion

Care needs to be taken where the movement of the truss results in eccentric loading of the support beams. If not considered and detailed, torsion of the support beam can cause catastrophic collapse!

Have any project that you would want to discuss?

Book a meeting with us and we will assist you with the structural design and analysis of your structure to help you produce a structure that is fit-for-purpose and capable of resisting all applied loads without failure during its intended life.

Like this article?

Subscribe to our newsletter to receive a weekly email from Yenem’s director, Dave Meney.