From printing replacement human body parts to assisting with running repairs on voyages to Mars, many predictions are being made for how 3D printing may soon improve the whole of humanity.

Will 3D printing have a place in construction and mining? It already has. The future of construction is 3D printing.

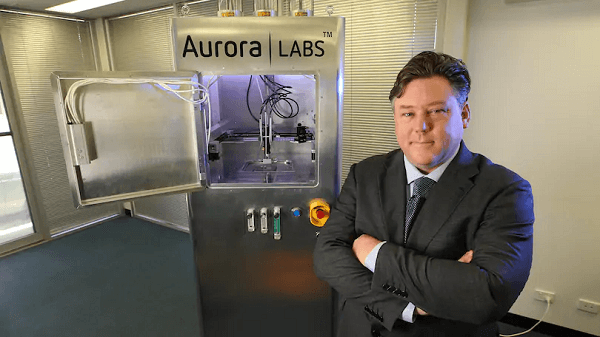

FMG are exploring the applications of additive manufacturing in mining with Aurora Labs – Perth’s own metal 3D printing company at the forefront of this emerging industry.

More boldly, Dubai has announced that 25% of the city’s new buildings will be made using 3D printers by 2025. Starting with components and moving towards entire buildings being “printed”, it aims to reduce labour by 70% and cut costs by 90% across different sectors, according to the Dubai Future Foundation.

The Dubai Future Foundation was set up to provide a road map for the government to consider and prepare for how technology will shape the industries of the future. It aims to make Dubai the world’s “3D-printing hub” by 2030.

The UAE tested the potential of 3D-printing in the construction industry in 2016 when it opened what it claimed was the world’s first building to be made using the technology. The building, called the “Office of the Future,” was created by a 3D concrete printer with a robotic arm that was 6 metres high and 12 metres wide.

The people needed for the build included one technician to monitor the printer, seven people to install the building on site, and a team of 10 electricians and specialists to take care of the mechanical and electrical engineering. That’s it!

The Foundation says that labour costs were cut by more than 50% compared to traditional costs of constructing a building of similar size. Printing took 17 days and the office was installed (minus services, interiors and landscape) in just two days. The future of construction is 3D printing to save time and reduce material and labour costs.

Not just UAE. Nantes, in France, claims it’s the first location to make a 3D-printed house. The five-room, 95 square metre property houses a local family qualifying for social assistance. The city authorities are considering developing an entire district of such homes in a bid to close the country’s affordable housing gap. Globally, this gap is estimated to be 330 million urban households and growing by more than 30% to 440 million households, or 1.6 billion people, by 2025. The future of construction is 3D printing to house the homeless.

Too futuristic? Well be careful not to be left behind. Kodak (forgot to embrace digital media) and Borders (thought books alone would let them thrive) are good hindsight lessons for those who think the current methods of construction will continue forever.

Dubai has the mindset of a Futurist. We all need that mindset – to be willing to take risks, to accept innovations, to be open to new ideas and possibilities.

Yenem is. We’re thrilled to be just weeks away from testing a prototype structure that will see steel structures of the future connected with our patented 3D printed altCONNECT connector.

How does altCONNECT work?

altCONNECT is a new way of connecting steel members: Without bolts. Without Welds. We’re challenging the current manufacturing methods used to construct mining structures where sections and plates are bolted and welded together.

Learn more about altCONNECT by clicking the the link below.