Every plant owner/manager strives for the same thing around their work site – to create a good, safe place where their employees can work productively and not have to worry about anything going wrong. Defective structures around the plant should be a major source of stress and anxiety. No one wants to worry about their staff being unsafe!

Any safety effort that helps to move towards a safe working environment should begin with having sturdy flooring for employees to walk on. Walkways and platforms are an important feature on any work site, and you want workers to be able to walk and work safely.

During a plant design/renovation, a structural engineer determines which type of flooring to use, and calculates how much weight and stress the walkways and platform floors can support.

The most common type of flooring used in mine sites is metal grating. This is because it provides a stable flooring base with good traction and can resist corrosion (especially galvanised grating).

Metal Grating Walkway

Ineffective Inspections – How Two Workers Almost Lost Their Lives!

During inspections, some inspectors ignore or overlook metal grating and defects can be missed. This is proving to be the case with the increased reported cases of falls due to defective or missing mesh panels in several mining sites around the country.

Some of the most recent cases were reported on 27 January 2021 and 4 February 2021, both in QLD.

By the way, Yenem’s engineers pay particular attention to platforms and walkways! It helps when the inspector is an engineer experienced in the design of structures being inspected.

How the Incidents Happened

According to a QLD Resources Safety & Health bulletin, both incidents are still being investigated, however the following is known:

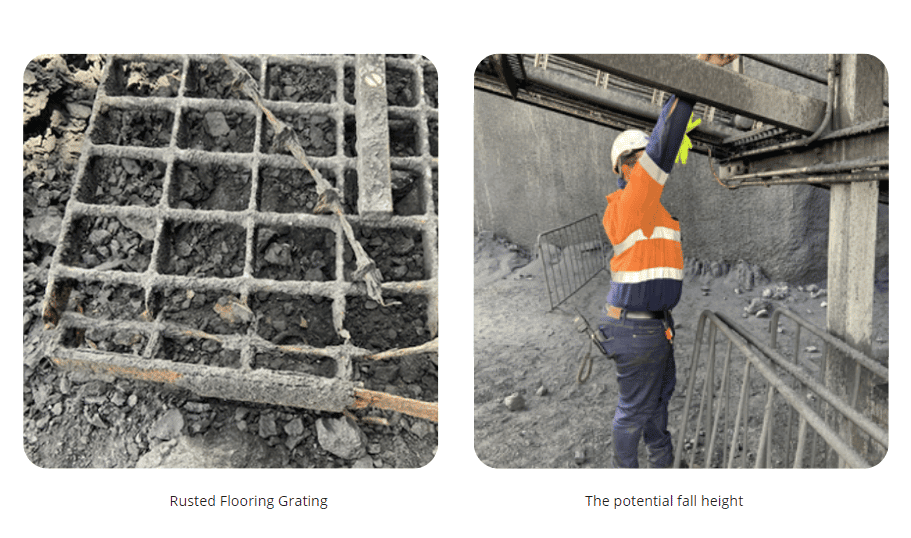

- Heavily Rusted Mesh – In the first incident, a dislodged mesh panel was found to be heavily rusted and the panel failed when the worker stood on it. Fortunately the worker was able to lower himself to the ground through the open section of flooring using the handrails and adjacent steel structure for support. The worker was exposed to a potential fall of approximately 2 metres

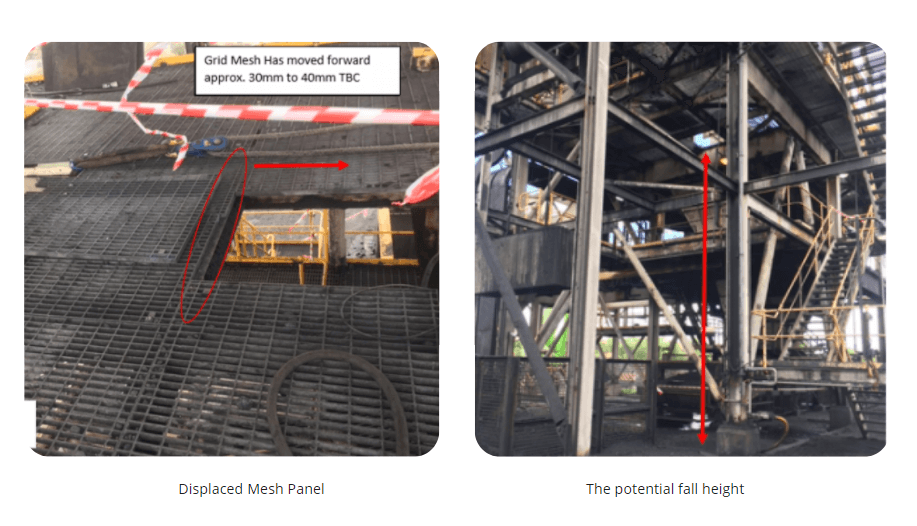

- Displaced Mesh Panel – In the second incident, the worker fell through a missing section of steel mesh floor. At the time of the incident, a roller screen in a coal crushing station was being pulled back into position. As the worker walked behind the work area, he fell through a section of floor mesh that wasn’t secured. Luckily he was able to stop the fall with his arms, however he potentially could have fallen 8.6 metres.

Key Issues Found

The key issues to be addressed by the Site Senior Executive:

- Ineffective inspections of walkways and platforms.

- Inspections of walkways and platforms not embedded in work management system.

- Inadequate structural assessment and audit by third party qualified engineers

- Corrective actions not actioned in timely manner.

- Housekeeping standards not maintained.

- Inadequate training and competency of persons conducting inspections.

- Mesh floor retention devices not suitable for environments subject to vibrations.

- Work not able to be completed as designed and management of change processes not followed.

- Mesh retention devices are typically not designed to take horizontal loading potentially leading to dislodgement of mesh panels.

Eliminating/Minimizing Health and Safety Risks

Other similar incidents have occurred, and recommendations were given after the incident had already taken place. But do we have to wait until a potentially fatal incident happens before we rectify things?

A safe and healthy workplace does not happen by chance or guesswork. You have to think about what could go wrong at your workplace and what the consequences could be. Then you must do whatever you can (in other words, whatever is ‘reasonably practicable’) to eliminate or minimise health and safety risks.

Inspecting loose bolts on a mining platform.

Our team of competent engineers can help you with that through keen and regular inspections that can help locate and identify such structural defects and advise on the best remedial solution before they prove to be costly.

Need a Site Inspection?

Our premium service is a proactive one, involving ongoing inspections at a frequency that suits the type of plant.

Find out more about (SAM) – Our Structural Asset Management Service by clicking the button below.