Structural Failure and How to Stop the Next One

In modern mining operations, virtually every aspect of the process is monitored meticulously. From flow rates and pump performance to slurry density and conveyor belt speeds, data is king. Yet there’s one crucial asset that often flies under the radar until disaster strikes: the structure itself.

This blind spot can cost millions. We’ve witnessed it firsthand.

A Structural Failure: The Case of the Failed Stacker

One of our clients suffered a dramatic structural failure on a stacker, a piece of equipment vital to their production line. What went wrong?

The cable stays, designed to remain taut and keep the structure stable, relaxed unexpectedly. This caused columns that should have been in compression to experience tension instead. Over time, bolts failed, and with them, the stacker collapsed.

This wasn’t a design flaw. It was a knowledge gap: the client simply didn’t know their structure’s condition was changing until it was too late. The result? A structural failure that led to unplanned shutdowns, costly repairs, and endless manual inspections to patch things up, all expensive and disruptive.

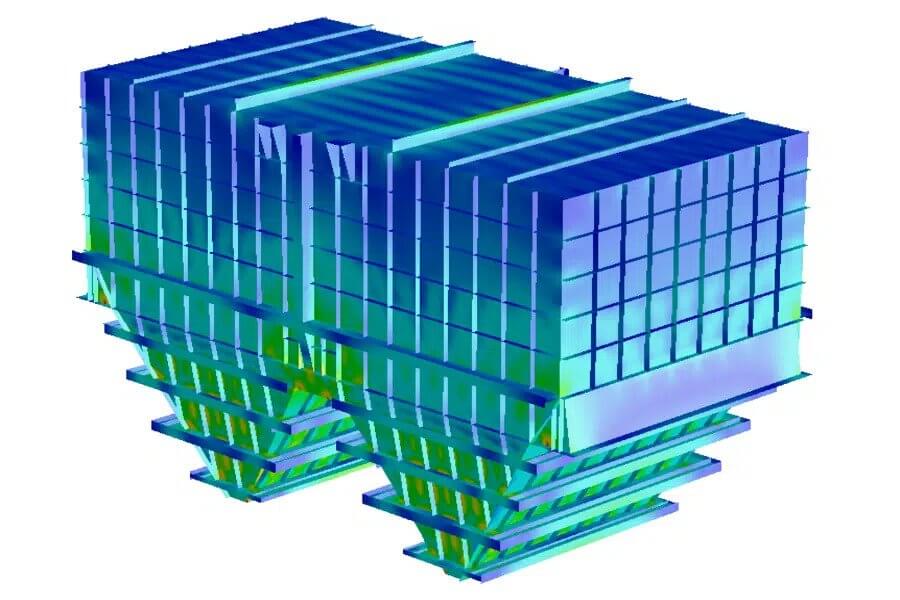

After the structural failure, we helped them create a digital twin of the stacker: a real-time computer model tracking stresses and deflections. But without sensors feeding live data, the model remains a dormant tool. Without that connection, they’re no better off than before.

What is Structural Health Monitoring?

Structural Health Monitoring (SHM) is about installing sensors on critical assets to collect real-time data on their condition. These sensors track parameters like:

- Strain: How much a structural member stretches or compresses

- Vibration: Frequencies and amplitudes that may cause fatigue

- Deflection: The bending of beams or columns

- Temperature: Important for materials affected by thermal expansion

With SHM, you can detect:

- Overloading

- Progressive deterioration

- Unexpected structural changes (including unauthorised modifications)

- Early signs of fatigue or corrosion

- It shifts maintenance from reactive to proactive.

Digital Twins: The Nervous System of Modern Structures

At Yenem, we use Akselos, a cutting-edge software platform that builds physics-based digital twins of your structures. These models continuously ingest sensor data, compare it to design expectations, and alert you when something is off.

For mining operations already accustomed to monitoring process metrics, integrating a structural monitoring dashboard is a natural upgrade, not a radical change. When the digital twin detects abnormal movement or stress, it’s your early warning system for corrosion, impact damage, or potential structural failure.

A Smartwatch for Your Stacker?

We all rely on Fitbits and Apple Watches to monitor our health, tracking heart rate, steps, and sleep patterns, alerting us to potential issues before they become emergencies.

Why wouldn’t you want the same for a 300-tonne stacker?

A structural digital twin acts like a smartwatch for your equipment:

- Constantly reading asset performance

- Sending alerts when performance deviates

- Maintaining a digital memory of stress accumulation over time

In fact, it can be even more precise than wearable tech, because it accounts for material properties, loading conditions, and design limits.

How Yenem Makes It Work

We design for sensors from the start by:

- Identifying optimal sensor locations

- Building detailed Akselos models based on your design or existing assets

- Connecting the digital twin to live data streams for a responsive, “living” replica

- Advising on data interpretation and proactive maintenance strategies

Our approach helps you prevent structural failures before they occur without complicating your plant operations.

Don’t Wait for the Crack

The client who lost their stacker wasn’t ignoring engineering principles; they simply lacked visibility into the structure’s evolving condition. By the time the signs of structural failure were visible, it was too late.

SHM and digital twins aren’t about overengineering. They’re about preventing structural failures by making your structures as smart and data-driven as the rest of your mine.

If you’re already tracking process performance, it’s time to bring your structures into that picture. Think of it this way: if you wouldn’t run a marathon without your smartwatch, why run your plant without one for your structures?

Ready to upgrade your mining infrastructure?

Talk to Yenem about designing for structural monitoring and building a digital twin that delivers real-time durability; not just static design drawings and subscribe to our newsletter for more business insight.