Structural Compliance Isn’t Optional. It’s the Only Option

It started with a seemingly routine inspection. A visit from the Mines Department. No warning, no prep time. Within hours, a major section of the plant was shut down by prohibition notices. Production stopped. A structural investigation followed. Delays mounted. Revenue losses climbed into the hundreds of thousands.

This isn’t an isolated story. It’s a wake-up call about the importance of structural compliance. Not just ticking a box, but actively maintaining the integrity of every component supporting your operations.

Structural Compliance and the Regulator: The Changing Landscape

If you’ve lost track of who’s in charge of mine safety in WA, you’re not alone. Since 1982, the Mines Department has been rebadged more times than a fleet of used utes. Most recently, in June 2025, DMIRS was split into two:

- DLGCIRS (Department of Local Government, Commerce, Industry Regulation & Safety)

- DMPE (Department of Mines, Petroleum & Exploration)

Still with us? Great. Because while the names change, the Mining Act 1978 and Mining Regulations 1981 remain in effect. What’s new, and now carrying significant weight, is the Work Health and Safety Act 2020, along with the Work Health and Safety (Mines) Regulations 2022.

The message from the regulator is clear. Ignorance of the law, especially structural non-compliance, is no defence. If you’re not on top of it, you’re already at risk.

The Cost of Non-Compliance: More Than Just Fines

Here’s where things get serious. DMPE, equipped with fresh legislation and greater authority, wasted no time issuing record-breaking fines to operators who failed to maintain a safe workplace.

And “safe” now means much more than it used to.

It means your conveyor support structures are sound. It means stairways, platforms and handrails are free from corrosion. It means unengineered modifications and DIY fixes aren’t compromising the integrity of the entire system. In short, you can’t wait for something to collapse before you act.

A recent example involved a crushing plant in the Darling Ranges. A random inspection by the Mines Department revealed corrosion, material build-up and undocumented site modifications. The result was prohibition notices, a partial shutdown and a full-scale structural compliance assessment under urgent time pressure.

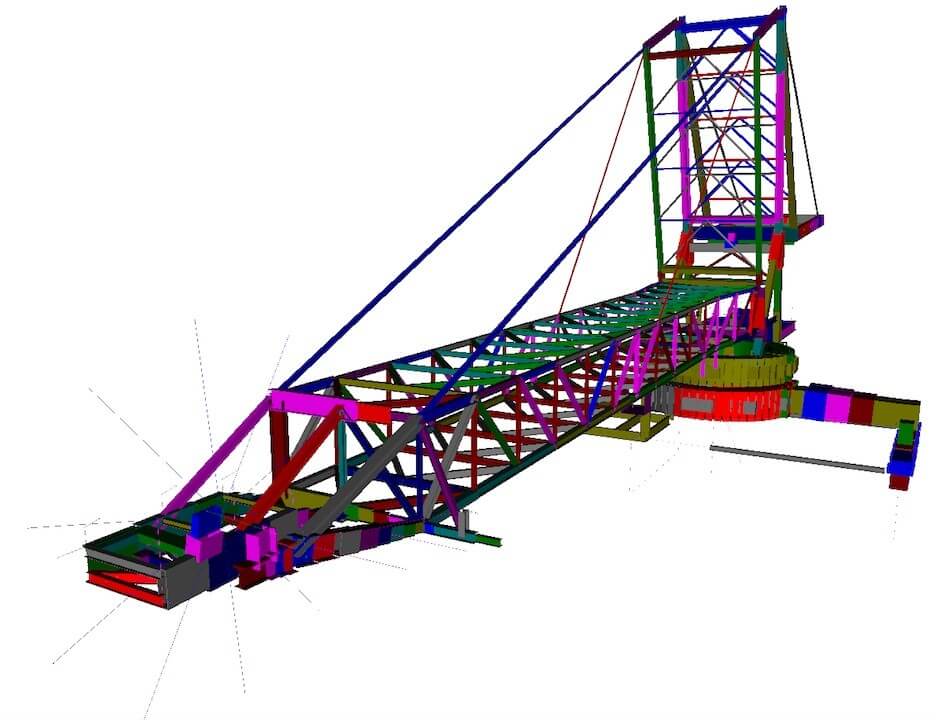

Our team at Yenem Engineering was brought in to evaluate everything. Conveyor gantries, screen decks, crusher supports and access systems were all assessed. The issues were real, the timeline was tight and the consequences of further delay were severe.

The Case for Proactive Structural Compliance

So what’s the alternative?

A proactive compliance culture.

Because here’s the reality. Structures degrade. Water leaks, vibrating machinery, mobile plant damage and environmental exposure all take their toll. Without a system of regular inspections, routine maintenance and engineered repairs, it’s only a matter of time before the regulator, or worse, an accident, forces your hand.

You might already have an asset that looks fine from the outside. But we’ve seen time and time again that the biggest risks are often hidden. Corrosion under grating. Fatigue at connection points. Rusted-through pipe supports concealed by material build-up. These problems aren’t visible during a quick walk-through. They require a deliberate and informed inspection process.

Structural Compliance Is a Culture, Not a Checklist

The companies that stay out of trouble don’t just react to problems. They anticipate them. They inspect based on the risk and consequence of failure. They act on recommendations, follow up, and build structural compliance into their operating culture.

They also partner with specialists like Yenem Engineering Services. Not just when things go wrong, but before they do.

Because structural compliance isn’t about red tape. It’s about keeping your people safe, your operations running and your business out of the headlines.

Need help staying compliant?

Don’t wait for a surprise inspection to reveal critical issues. At Yenem Engineering Services, we specialise in structural inspections, assessments, and reporting that help you stay ahead of regulatory risk. Whether it’s a once-off assessment or a structured inspection program, we’ve got you covered.

Book your free consult today. Don’t wait for the regulator to find the problems you didn’t know you had. Get ahead of the risk with a free, no-obligation consult from Yenem Engineering Services.