Structural Installation: The High Stakes of Non-Compliant Designs

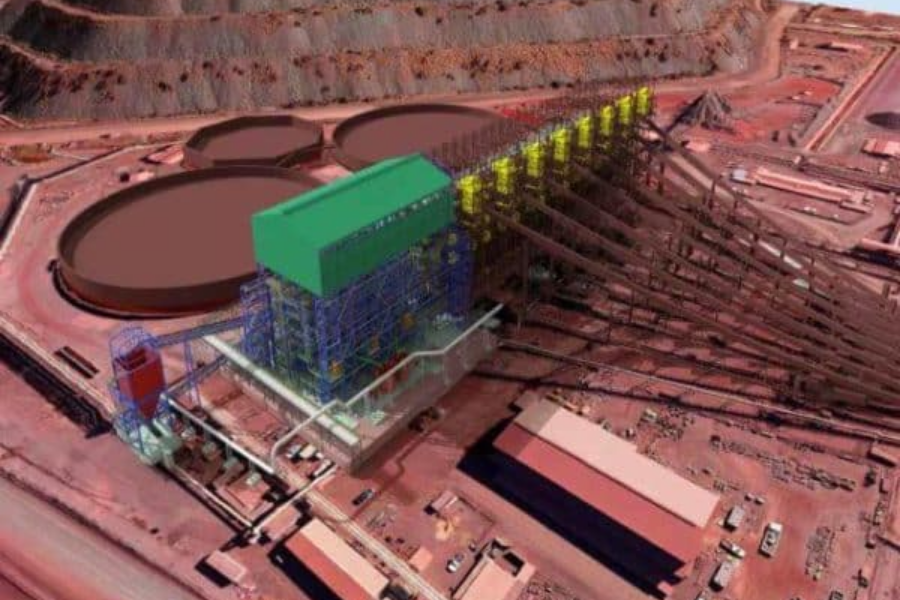

A large structural installation project in Western Australia recently hit a frustrating and costly snag. What was meant to be a straightforward build, including grain silos, support steelwork, conveyors, and access platforms, was suddenly brought to a halt.

Why? The structures, designed overseas to US engineering codes, weren’t certified to meet Australian Standards (AS). Despite having landed on-site and ready for assembly, local authorities issued a stop work order until full engineering certification could be provided.

This real-world scenario underscores a vital point: in Australia, structural installation must meet local compliance standards regardless of where the design originated.

The Cautionary Tale: A Structural Installation Gone Sideways

This project included a range of complex structures:

- Grain silos

- Conveyor galleries

- Steel support frames

- Ladders, platforms, and catwalks

All components were designed and fabricated overseas. On paper, everything looked solid and compliant with US codes and engineering assumptions. But as the project arrived in Western Australia, the local shire council intervened. Installation could not commence without an Australian-certified engineering review.

The consequences were immediate:

- Downtime while waiting for certification

- Pressure from stakeholders as timelines slipped

- Risk of missing critical deadlines for the upcoming harvest

This structural installation quickly turned into a cautionary tale of what happens when design compliance is assumed instead of confirmed.

Lessons from the Field: What You Need to Know

Imported Design ≠ Compliant Design

It’s a common misconception that international engineering standards are interchangeable. But they’re not. Australian Standards (AS) differ significantly from US or European codes, especially in areas such as:

- Wind load calculations

- Access and egress provisions

- Welding and fabrication tolerances

- Soil interaction and foundation design

A design that looks structurally sound under US codes might fall short under Australian regulations. That difference can lead to retrofits, rework, or even complete redesign.

Local Regulators Have the Final Say

Even if your supplier is reputable and the materials are on-site, local councils have the authority and responsibility to enforce Australian compliance. Without AS-certified documentation, a council or the Mines Department can stop the project.

This enforcement is not negotiable. It can lead to serious cost blowouts, legal liability, and strained relationships with clients or investors.

Design Assumptions Must Be Verified

Assumptions do not equal engineering. Every design element must be checked against site-specific conditions and Australian regulations. That includes:

- Live and dead loads

- Soil capacity

- Structural tie-in points

- Load paths and deflections

Skipping this step is like gambling with safety. The consequences can be severe.

Certification Isn’t a Tick-Box. It’s a Process

Certification isn’t a formality. It is a technical and legal review of the structure’s safety and compliance. If left until the last minute, it can delay the entire project, especially if critical data is missing or the design doesn’t align with local standards.

How Yenem Engineering Helped Rescue the Project

Yenem Engineering Services was brought in to review and certify the design to Australian Standards. Our scope included a detailed assessment of:

- Silo support structures

- Conveyor galleries

- Ladders, walkways, and platform connections

We identified areas needing recalculation, clarified documentation, and recommended minor design updates. Working closely with the client, we helped streamline the certification process and move the project back on track. This helped minimise further delays before the harvest season.

Our experience and rapid response made a real difference when it mattered most.

Structural Installation: Don’t Leave Compliance to Chance

Whether it’s a silo, conveyor, or platform, structural installation in Australia demands full compliance with local standards. That means getting a certified structural engineer involved early, especially when importing overseas designs.

Don’t wait for the council engineer or the mines inspector to stop your job.

Book a free consult to review and certify your designs to Australian Standards before your project is at risk. With over 30 years of experience, we help ensure structural installations go up safely, smoothly and on schedule.

Contact Yenem today before assumptions cost you everything.