Downtime cost a fortune. Surprisingly, it’s at the same level today as it was 30 years ago.

Why? Things are so much better these days. We’re in the future now, with increased reliability and smart, innovative machines!

The Failure of A Single Item Can Be Enough to Cause a Total Plant Shutdown.

I was at a gold mine recently – they had a problem and things weren’t running that day.

I did some maths:

Throughput = 8.0Mt paOre grade = 2.4g/t AuRecovery rate = 90%

So in a year, that’s 17.3 tonnes of gold.

The gold price is currently around A$1,850/ounce, or $59,000/kg.

So total plant shutdown costs $2.8M/day!

What?!!

This plant has poor inspection and maintenance procedures, a fairly average plant design (built to a price, of course!), and yet it’s capable of banging out 50 kg of the glittering stuff each day. You’d think preventative maintenance would be high on the agenda, but nah, production is! And that’s what hasn’t changed over 30 years – mindset.

Here’s just 5 steps that will reduce unplanned shutdowns, and won’t cost you $3 million bucks a day!

1. Calculate the Dollar Cost of Downtime

Actually, that “cost” is an arguable one. But in any case, true downtime costs include, on top of lost production, loss of staff productivity, manhours devoted to rescheduling, costs of repairing broken equipment, time spent satisfying customers.

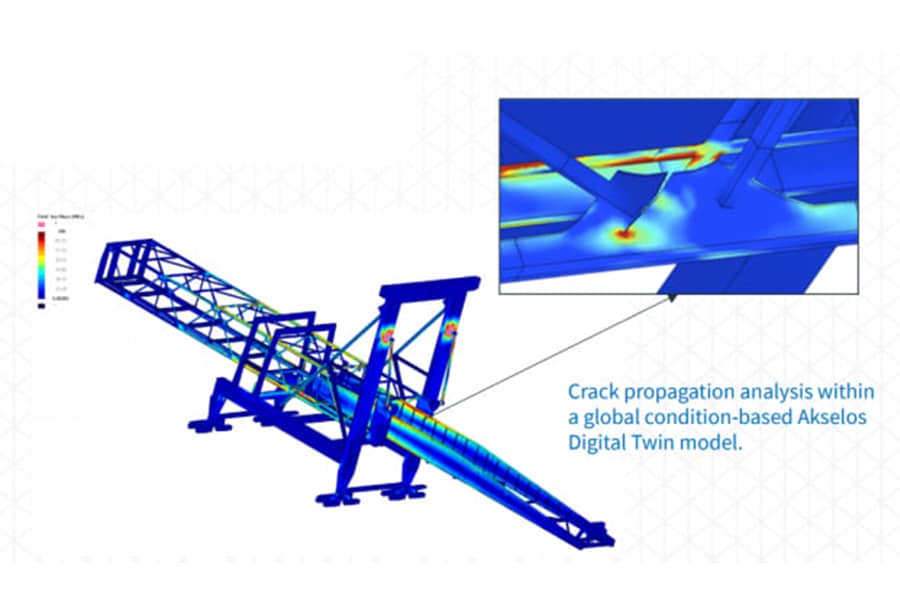

2. Move Towards ‘Predictive Maintenance’

Low-cost sensors can detect, prevent and reduce downtime in a process plant. They can detect inputs like vibration, temperature, heat and light. They can then send data back to the control room to alert production managers and thus stop downtime before it happens. Process plants already have lots of sensors. How many are there to monitor problems with equipment and structures, and how many are there to monitor production levels?

Industrial Sensors

3. Harness Your Data

At that gold plant, very little information was available in the way of equipment and structural drawings. It’s not even that old! Searching for information is a huge time-waster. Why not use your iPad to scan a nearby barcode and pull up drawings, manuals, MSDS, etc. from a cloud server. Mark them up following changes and improvements or to communicate requests with the design team, and put them back.

Industry 4.0

4. Stick to A Preventative Maintenance Schedule

Don’t run it till it breaks!

Equipment and structures can’t last forever, but a good preventative maintenance schedule will increase their life. Maintenance reduces the probability of failure and hence downtime, increases overall process effectiveness, improves safety and increases productivity.

Be consistent too – no point in vacuuming and polishing the crushers and screens if their supporting structures are gathering cracks and getting ready to collapse!

5. Change the mindset from ‘reactive’ to ‘proactive’

When something breaks, someone will always be within earshot saying “I knew that would happen!”

Find that person. Change that person. The staff who have the potential to prolong downtime events are often in the best position to prevent it in the future.

You can reduce operator error if you empower and train your operators to diagnose and fix problems and put in place actions to prevent future downtime events through maintenance schedules and accurate documentation.

Whether it’s a preventative maintenance schedule, operator training, sensor technology or improved data management, there’s one common factor that will determine its success – employee mindset.

-

- No system will work if staff aren’t committed to its success

- No amount of policy will ensure equipment is checked and maintained.

- It’s people who make the wheels turn, every day. So work your way through this list with culture and staff empowerment front of mind.