Introduction

In the realm of mining structures, ensuring safety and reliability is of paramount importance. Every component used in these structures must be carefully selected and designed to withstand extreme conditions and heavy loads.

Among the various components, bolt washers may appear insignificant, but they serve a critical role in enhancing structural stability and preventing potential hazards. This article explores the structural importance of bolt washers in mining structures, shedding light on their functionalities and benefits.

The Role of Bolt Washers

Mining Structures are subject to dynamic forces, vibrations, and constant stresses. Bolt washers, which are thin, flat discs made of metal or composite materials, are inserted between the bolt head or nut and the connected structural elements. They serve multiple essential functions, including:

Load Distribution: Bolt washers act as load distributors, evenly distributing the clamping force applied by the bolt. By spreading the load over a larger surface area, they minimize stress concentration and prevent localized damage to the structure.

Protection Against Loosening: Vibrations and dynamic loads can cause bolts to gradually loosen over time, compromising the integrity of the mining structure. Bolt washers provide a cushioning effect that helps to maintain the clamping force and prevent bolt self-loosening, thereby increasing safety and reliability.

Compensation for Surface Irregularities: Surface imperfections on the bolt head, nut, or connected elements can result in uneven distribution of force. Bolt washers compensate for these irregularities, ensuring a more uniform distribution of load and reducing the risk of failure due to localized stress concentration.

Types of Bolt Washers for Mining Structures

Various types of bolt washers are available, each designed to address specific requirements in mining structures. Some commonly used types include:

Flat Washers: These are the most basic type of bolt washers, featuring a simple flat design. They provide a larger surface area for load distribution and are often used in applications where minimal deflection is required.

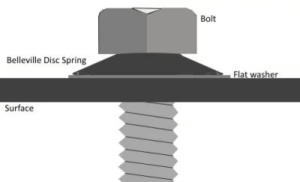

Spring Washers: Also known as Belleville washers, these washers have a conical or curved shape, offering spring-like characteristics. Spring washers absorb vibrations and help maintain the bolt’s tension, preventing loosening under dynamic loads.

Lock Washers: Lock washers, such as split washers or toothed washers, have serrations or teeth that bite into the bolted surfaces. This creates resistance against rotation, preventing the bolt from loosening due to vibrations or external forces.

Belleville disc spring washer used with a flat washer to help spread load

Benefits of Bolt Washers in Mining Structures

The utilisation of bolt washers in mining structures provides several significant benefits:

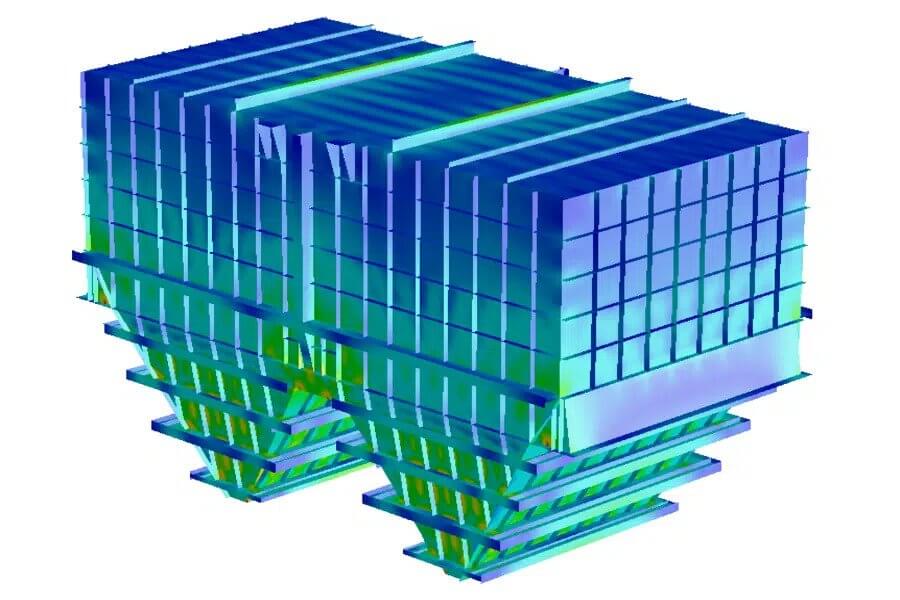

Enhanced Structural Stability: By promoting even load distribution, bolt washers minimise stress concentrations and improve structural stability. This helps to prevent failures, maintain the structural integrity of mining structures, and safeguard personnel working in these environments.

Increased Safety and Reliability: Bolt washers play a crucial role in preventing self-loosening of bolts, which can lead to catastrophic failures. By maintaining the clamping force, they enhance safety and reliability in mining structures, reducing the risk of accidents and unplanned downtime.

Improved Resistance to Dynamic Loads: Mining structures are subjected to dynamic forces, such as vibrations and ground movements. Bolt washers absorb and distribute these loads, reducing the impact on the structure and mitigating the risk of fatigue failure.

Considerations for Bolt Washer Selection

When selecting bolt washers for mining structures, several factors should be considered:

Material Compatibility: Choose bolt washers made from materials that are compatible with the bolt and structural elements. Factors such as corrosion resistance, temperature tolerance, and chemical resistance should be evaluated to ensure long-term reliability.

Washer Dimensions: The size and thickness of the washer should be appropriate for the specific application and the bolt size. Proper dimensions ensure optimal load distribution and prevent unnecessary stress concentrations.

Environmental Factors: Consider the environmental conditions in which the mining structure operates, such as temperature variations, humidity, and exposure to chemicals. Select washers that can withstand these conditions without compromising their functionality.

Conclusion

Bolt washers may seem like small components in mining structures, but their role in enhancing safety and reliability cannot be understated. By distributing loads, preventing loosening, and compensating for surface irregularities, bolt washers contribute to the overall structural integrity of mining structures.

Proper selection and installation of these washers are crucial to ensure optimal performance and minimize the risk of failures. In the challenging and demanding environment of mining, bolt washers are indispensable for maintaining the stability and longevity of these vital structures.