We’ve been in and around mining and industrial structures for over 30 years, and we’ve seen some shocking things in our resource-abundant backyard.

Poor communication and incompetent design are two of the issues that lead to creation of structures that are not even suitable for their purpose.

Busy times bring the bad engineers out of wherever they’ve been. As we head towards our next boom it will pay to be careful who you engage to design safe structures, but what about those that have already been built?

There’s plenty at risk in the present and future at our mines and being reactive when a structural failure occurs is not going to cut it.

Gantry Failure (Image courtesy of Australasian Mine Safety Journal)

Are Regular Inspections Enough?

It’s not enough to just have an inspection program, you also need the right eyes on site. And just ensuring those eyes belong to a structural engineer isn’t necessarily enough to reduce risk of failure and injury on site.

The best inspectors of mine site structures are indeed structural engineers, but more than that, you need design engineers with years of experience designing mining structures and hence have a great understanding of :

? What is and isn’t critical

? What does and doesn’t need to be replaced

And with that experience they are – we are – equipped to carry out the necessary quantitative assessment to ensure if remedial work is required at all, and if so, it’s sufficient but not excessive.

Corroded Steel

Be Proactive!

Are you an asset owner, or manage assets on behalf of your clients?

This is what should happen before the DMIRS or WorkSafe inspector comes knocking:

✔️ Include structures in the asset register alongside the equipment that is regularly inspected and maintained.

✔️ Assess the adequacy and suitability of designs and modifications to all existing structures.

(i) Structures that are unchanged need to only comply with the original design specifications, codes and standards.

(ii) Modified structures need to comply with codes and standards applicable at the time of the modification. Not just the modifications, the whole structure.

✔️ Collate drawings, calculations and other documentation.

✔️ Establish a proactive monitoring and maintenance program for all structures.

How We Can Assist With That!

We can arrange all the above for you or your client for an affordable fee. Production continues without breakdown, and we reduce risk to a manageable level to meet the obligations under the mines safety and inspection act and regulations.

We can provide:

? A secure cloud-based database of your structural assets, including drawings, specifications, modification logs, maintenance logs etc

? Review of previous inspection reports and pending recommendations

? Help to assess the structural risks and degree of urgency

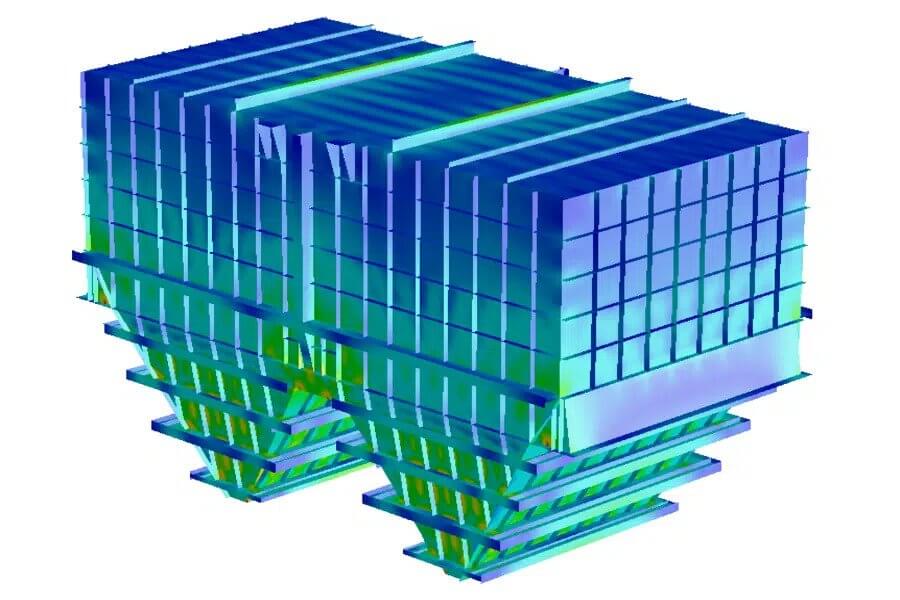

? 3D digital models of your structure from photos and scan to assist in managing the structures changes due to damage throughout their entire lifetime.