How Poor Engineering Shows Up on Projects

There’s always the temptation to speed things up. A client is pushing, a deadline looms, or the pressure’s on to get steel in the air and concrete above ground. That’s when the shortcuts creep in. But in structural engineering, poor engineering is never really quicker, and it’s certainly not cheaper.

Cutting corners doesn’t just chip away at the schedule. It also compromises safety, invites hidden costs, and leaves reputations hanging by a thread.

The Risks of Poor Engineering

Safety compromised.

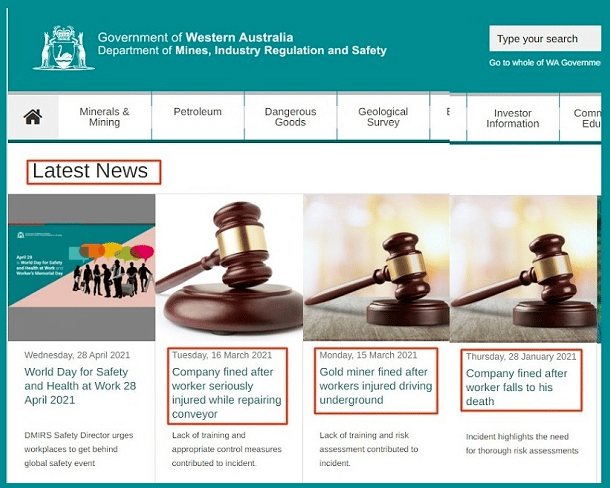

The ultimate responsibility of an engineer is safety. Poor engineering, whether through bad calculations, sloppy documentation, or unchecked site changes, puts people and assets at risk. A design that “looks fine” isn’t good enough when lives depend on it.

Hidden costs.

The irony is that poor engineering usually costs more. Rework, fabrication issues, project delays, and even litigation are the fallout from shortcuts. What looked like a cost-saving shortcut quickly turns into an expensive detour.

Reputation damage.

Clients and regulators have long memories. Poor engineering erodes trust, and once trust is lost, it’s hard to win back. An engineer’s reputation is built over decades but can be undone in one poor project.

The Hidden Dangers of Poor Engineering in Structural Projects

Incomplete or undocumented calculations.

We regularly review the work of others, and sometimes the calculations are frankly abysmal. You can tell the only calculations they bothered with are the ones submitted, and they’re of such poor quality that you wonder what the rest looked like.

There’s a term we use in the industry: Okay by Inspection (OKBI). An experienced engineer might occasionally rely on it, knowing from decades of practice that if the calcs were run, they’d check out. But when a graduate tries to pull the same trick? That’s poor engineering. How can someone with no depth of experience rely on it?

Substituting substandard materials.

Material substitution isn’t inherently bad; supply constraints can force it. The problem is when it’s done poorly. Changing a material often changes the geometry, which can spiral into fabrication headaches if the design isn’t updated, the models revised, and the drawings corrected. Poor engineering ignores this chain reaction.

“She’ll be right” site alterations.

We see this all the time in CROSS reports: construction engineers deciding they know better, making site changes without notifying the design engineer. They think it’ll take too long to get a sign-off. The result? Poor engineering baked into the build, with risks nobody has assessed.

Why Integrity Beats Poor Engineering Every Time

At Yenem Engineering Services, we take the position that designs must always be defensible and documented, even if that means rework after the first issue. That’s not wasted time; that’s integrity.

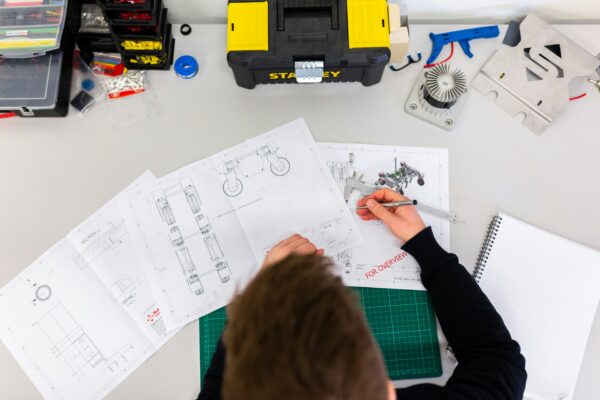

Third-party reviews are another safeguard. The very act of preparing your work for independent eyes makes you more alert to gaps or errors. You design better because you know it has to stand up to scrutiny. Poor engineering doesn’t survive that process.

In the long run, integrity doesn’t just save money but also builds trust. Clients know when you’re cutting corners, and they know when you’re not. Trust is what brings them back.

Poor Engineering Is Never a Shortcut, Only a Detour

The truth is that doing it right the first time is the cheapest, fastest, and safest option. “Fast track” projects that cut out engineering time almost always run slower in the end. They trip over rework, delays, and conflicts that could have been avoided with proper design.

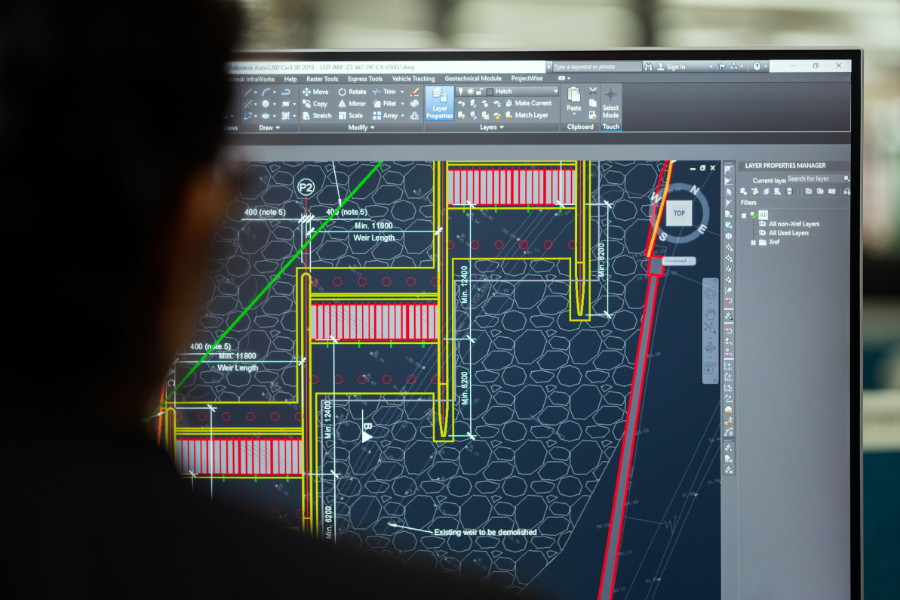

Clients sometimes think nothing is happening until concrete is poured and steel is up. But the real work, the progress that matters, happens in the calculations, in the drawings, and in the revisions no one sees. That’s not wasted time. That’s engineering done properly.

Don’t let poor engineering put your project, your budget, or your reputation at risk. What looks like a shortcut in the moment almost always becomes the longest and most expensive road you can take.

The reality is that safe, efficient, and durable structures come from designs that are defensible, documented, and properly reviewed. At Yenem Engineering Services, we know the value of doing it right the first time and we stand behind every drawing and calculation we produce. Book your free consultation today and let us show you how avoiding poor engineering now will save you time, money, and stress later.