Bolts used in structural joints are designated by;

-

- Diameter

- Grade

- Tightening procedure.

For example, an M20-8.8/S bolt is:

20 mm in diameter with a metric thread, the ultimate tensile strength is 800MPa and the yield strength is 640 MPa (8.8 translates to 8x100x0.8=640), and it is tightened to (s) “snug tight”

Can you work out the yield strength of this bolt – M16-4.6/S?

If you got 240 MPa, you’d be correct.

That’s a mild steel bolt. We use these on handrails and holding down bolts in concrete but not much else.

Bolts are also tightened to a specification:

(S) – Being ‘snug’

(TF) – Friction type application

(TB) – Bearing type application

So How Snug Is ‘Snug’?

I hate that term, snug. It conjures up comfort like a blanket on a cold night, but actually ‘snug’ is defined as “the full effort of a man using a standard podger spanner or a few impacts of an impact wrench” which conjures up hard work!

Is the “man” Arnold Schwarzenegger or Woody Allen? Surely that would make a difference.

Is the tool a “standard podger spanner” or an impact wrench? Who know what the resulting tightness is?

Who really knows what the resulting tightness is?

After (S) comes (TB) and (TF) – both of these represent “fully tensioned” bolts.

TB and TF

The norm is TB – this means under loads the connections can slip such that the bolts bear against their 2 mm oversized hole.

For applications where building movement is not acceptable, TF is used. And the bolt uses friction to prevent it from slipping to the edge of the hole.

There’s a big difference in the preparation of the joint, but otherwise TF or TB means the bolt is stretched.

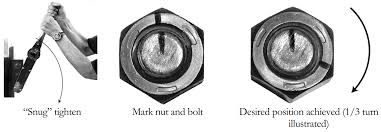

This is normally achieved by what is termed the ‘part-turn method‘.

You get the bolt snug tight (whatever that is), mark the relative position of the nut and bolt, and then keep turning the spanner a predetermined amount. If you asked a bunch of people many would say that amount is a quarter of a turn.

But AS4100 Table 24 shows 1/3, 1/2, 2/3, 5/6 and 1 turn – the required amount is dependent on the bolt length and the “disposition of outer face of bolted parts“.

It’s all very confusing. To further complicate things, some contractors will fake the marks and so a bolt inspected for tightness will pass and yet be some version of snug.

We know bolts are not always tightened and tensioned properly. Bolts discovered missing from connections during our structural inspections were probably there once, and rattled loose because they weren’t tightened enough.

But Wait! There’s Another Way (yay!)

Direct tension indicators (DTI’s) are available in the market place. I’m interested to know what percentage of structural bolts are tightened using them. Two I know about are “The Squirter” and “SmartBolts”.

The beautifully named Squirter is a washer containing an orange silicon that literally squirts from the interior of the washer creating a visual indicator of correct tension.

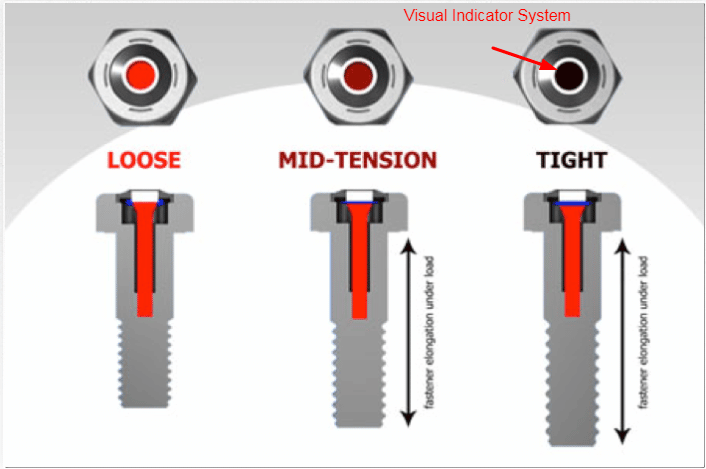

The SmartBolt is a US product, so I’m not sure who’s using it in Australia. This has a material in the body of the bolt and visible in the centre of the bolt head. It stretches when the bolt does, and changes colour from red (untensioned) to black (tensioned).

As engineers, we design our structures with the appropriate connections to ensure structural performance. Fully tensioned bolts are standard in our industry and snug bolts are standard in static structures like shopping centres.

It would be better if we were more specific. Using tensioned bolts where vibration is present to ensure connections remain intact and to mitigate against fatigue, but accepting snug bolts in more static locations. This way our budget could support the use of DTI’s and our structures could perform better or longer, reducing downtime and maintenance.