What CROSS Teaches Us About Compliance and the Cost of Compromised Structural Integrity

When engineering design goes wrong, it’s not just drawings that collapse. It can be trust, safety, structural integrity, and sometimes even lives. Enter CROSS; Collaborative Reporting for Safer Structures, a confidential reporting system for structural and fire safety incidents. Established in the UK, it allows engineers, designers, and construction professionals to share near misses, failures, and concerns without fear of blame.

It’s not about pointing fingers. It’s about learning. And improving.

Here are a few real-world lessons shared via CROSS; examples where shortcuts, mistakes, or poor decisions led to real consequences.

1. Steel Canopy Collapse During Completion

A 57m single-span steel truss failed catastrophically during the final stages of a new school build. The collapse of a canopy supported by the truss sent five workers, 15 metres above ground, crashing down. Thankfully, all survived but with significant injuries.

So, what went wrong?

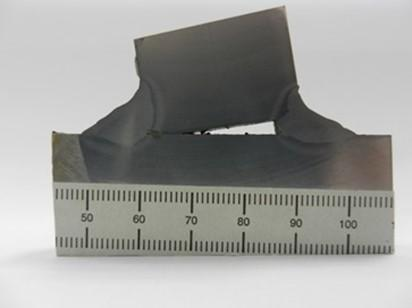

The failure stemmed from under-sized fillet welds at critical joints. The design called for an 80-degree bevel but for “ease of production,” plates were cut at 90 degrees, leaving a 4.5mm gap in the joint. This resulted in a weld throat of just 4-7mm, instead of the required 10.6mm.

Lessons:

- One flawed joint caused an “unzipping” of the entire structure. Structural redundancy matters.

- Deviation from the design, no matter how minor it seems, can have drastic consequences, especially during construction phases when elements haven’t reached full stability and structural integrity is most vulnerable.

- All modifications to the design must go through the design engineer; fabricators and site teams aren’t the final authority.

2. Wrong Steel Grade Supplied

A structural engineer specified S355 steel. That’s what the drawings showed. That’s what the fabricator claimed to supply.

But while cleaning the steel, someone noticed something odd. The mill labels had been painted over. On removing the labels? S235, not S355. Further investigation showed thinner hollow sections had been delivered than were specified. Cheaper, weaker, and non-compliant.

Lessons:

- The supply chain can, and sometimes will, try to cut corners to save a buck at the expense of structural integrity.

- Material certificates aren’t optional; they need to be checked and verified.

- Every element, from drawings to delivery, must be validated before it’s considered “fit for purpose.”

3. Connection Botched During Strengthening Work

Retrofitting is always tricky, but this case shows how dangerous it can become when field teams go “off script.”

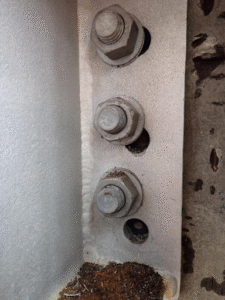

An end plate had incorrect bolt hole spacings. Instead of reporting it and getting it redone, the site team just drilled extra holes to “make it fit.” The result? Weakened connection, unexpected flexibility, and potential second-order effects that were never designed for, seriously undermining structural integrity.

Lessons:

- No on-site fix should ever bypass the design engineer. Period.

- Every connection detail matters, and any deviation without approval compromises structural integrity.

- Supervision and inspection must be competent and consistent. Hope is not a strategy.

What We Learn from These Failures

All these cases point to one thing: compliance is not bureaucracy. It’s an engineering discipline. It’s what ensures structures don’t just look right, but are right.

Here’s where failure creeps in:

- In the design office, when drawings aren’t clear enough.

- In fabrication, when specs aren’t followed or materials aren’t verified.

- On site, when assumptions replace approvals and “near enough” becomes “good enough.”

At Yenem, we prepare every design, report, and calculation with scrutiny in mind from regulators, peers, or clients. We’re not here to tick boxes. We’re here to ensure that what’s designed works, and what’s built lasts.

When we review designs by others, we look for the tell-tale signs: missing certs, ambiguous weld notes, undocumented site changes. Because if we don’t ask the hard questions, failure just might.

Compliance isn’t red tape, it’s the blueprint for safe, enduring structures.

Don’t Let Assumptions Undermine Structural Integrity

Book a free consult with Yenem to review and certify your designs before issues arise. With over 30 years of experience, we ensure your structural solutions are compliant with Australian Standards and built to withstand scrutiny.

Structural integrity isn’t just about what’s on paper. It’s about what actually gets built. From weld details to material grades, we help you get it right the first time.

Contact Yenem today and protect your project from the costly consequences of oversight.